20+ Years Experience

Specialist Resin Flooring Installers

Enquire Today For A Free No Obligation Quote

Resin flooring is a type of flooring that uses a combination of resin and hardening agents to create a durable and long-lasting surface. It is commonly used in commercial and industrial settings due to its resistance to chemicals, abrasion, and impact. However, there might be instances when you would need to remove resin flooring, whether it’s to update the look of the space or to address issues with the existing flooring.

In this step-by-step guide, we will walk you through the process of removing resin flooring. But before we delve into that, let’s first understand what resin flooring is and why you would want to remove it.

Resin flooring is a seamless and smooth flooring option that provides a high-gloss finish. It is commonly used in areas where a hygienic and easy-to-maintain surface is required, such as industrial kitchens, hospitals, and warehouses.

There are various reasons why you might want to remove resin flooring. It could be due to wear and tear over time, the need for a different flooring material, or the presence of damage or defects that require repair. Whatever the reason may be, it is important to follow a systematic approach to ensure a successful removal process.

Stay tuned as we guide you through each step of the process, from preparation and safety precautions to the actual removal of the resin flooring. We will also address common challenges that may arise during the process and provide tips on when it’s best to seek professional help. We will share some preventative measures to help you avoid the need to remove resin flooring in the future. So let’s get started on this journey of undoing and redoing your flooring.

Resin flooring is a type of flooring made from a combination of resin and hardener. It is popular in industrial and commercial spaces because it is durable and resistant to chemicals, impacts, and abrasions. Resin flooring is also known for its seamless and easy-to-clean surface, making it hygienic and suitable for areas with high foot traffic. It can be customized with different colours and finishes to match the aesthetic of the space. Resin flooring is a versatile and reliable option for various applications.

One might want to remove resin flooring for various reasons. If the existing flooring has become damaged or worn out, it may be necessary to remove the resin coating for repairs or replacement. Changing design preferences or functional requirements may also require the removal of resin flooring to accommodate a different style or type of flooring. In some cases, the resin flooring may not have been applied correctly or may have developed issues over time, prompting the need for removal. For example, a homeowner decided to remove their resin flooring after discovering cracks and delamination caused by improper installation.

In this guide, we will provide a step-by-step approach to removing resin flooring. From safety precautions to necessary tools and equipment, we will cover everything you need to know. We will also help you evaluate the situation and create a solid plan. Additionally, we will guide you through the removal process and proper disposal of resin waste. Let’s get started!

Prior to removing resin flooring, it is important to prepare the area properly. This involves following the steps below:

By diligently preparing the area and gathering the appropriate tools, you can effectively initiate the process of removing resin flooring.

Taking appropriate safety precautions is essential when removing resin flooring. To ensure a safe process, follow these steps:

Wear protective clothing: Put on gloves, goggles, and a respirator to shield your skin, eyes, and lungs from harmful chemicals.

Ventilate the area: Open windows and use fans to guarantee proper ventilation and reduce exposure to fumes.

Prepare a safe work area: Remove any obstacles or tripping hazards from the space to prevent accidents.

Use the correct tools: Utilise tools specifically designed for resin flooring removal, such as scrapers and grinders, to avoid injuries.

Dispose of waste correctly: Seal and label bags containing removed resin waste, and adhere to local regulations for disposing of hazardous materials.

Step 3: Tools and equipment for removing resin flooring are vital for a smooth and successful process. You will need the following essential items:

With the correct tools and equipment, you can efficiently remove resin flooring and prepare the surface for any desired changes. Remember to always follow safety precautions and consult professionals if necessary.

When removing resin flooring, step 4 involves evaluating and planning to ensure a smooth and efficient process. Here are the key steps to follow:

By carefully evaluating and planning the removal process, you can minimize any potential issues and ensure the successful removal of the resin flooring. Remember to prioritize safety and follow proper disposal guidelines for any waste generated.

The removal process of resin flooring involves several important steps to ensure its effective removal.

Prepare the area by clearing out any furniture or obstacles.

Take necessary safety precautions such as wearing protective gear and ensuring proper ventilation.

Gather the required tools and equipment, including a scraper, heat gun, and solvent.

Evaluate the flooring and plan the removal process accordingly.

Start the removal process by first removing the top layer of the resin flooring.

Continue by removing the base layer using a scraper or heat gun.

Thoroughly clean the surface once the resin flooring has been removed.

Dispose of the resin waste properly in accordance with local regulations.

Proper disposal of resin waste is crucial to minimize environmental impact and comply with regulations. To ensure proper disposal of resin waste, follow these steps:

True story: A manufacturing company once mistakenly disposed of resin waste in regular trash bins, resulting in environmental contamination and costly fines. As a result of this incident, the company implemented proper disposal procedures to prevent future occurrences and ensure compliance.

Removing resin flooring can present several challenges that need to be overcome for a successful project. Here are some common challenges one may encounter:

To overcome these challenges, it is recommended to consult with professionals experienced in resin flooring removal. They can provide guidance, use proper tools and techniques, and ensure the safety and efficiency of the removal process.

When to Seek Professional Help?

Knowing when to seek professional help is crucial when dealing with the removal of resin flooring. Some DIY enthusiasts may attempt the process themselves, but there are certain circumstances where it is best to rely on the expertise of professionals. These circumstances include:

| 1. Extensive damage: | If the resin flooring is severely damaged or has deep stains that cannot be easily removed, it is advisable to consult professionals. |

|---|---|

| 2. Lack of experience: | If you have little or no experience in handling resin flooring, it is safer to call in professionals who have the necessary skills and knowledge. |

| 3. Time constraints: | If you have limited time available or cannot dedicate sufficient time to the removal process, professionals can complete the job efficiently and in a timely manner. |

| 4. Safety concerns: | The removal of resin flooring can involve the use of chemicals and specialized equipment. If you are unsure about handling these safely, it is best to leave it to professionals who have the proper tools and training. |

Remember, seeking professional help ensures a smooth and successful removal process, reducing the risk of mistakes or further damage.

Regularly clean your resin flooring to prevent the build-up of dirt and debris.

Follow the manufacturer’s guidelines for maintenance, including routine inspections and repairs.

Place protective mats in high-traffic areas to minimise wear and tear on the flooring.

Use gentle cleaning products that are specifically designed for use on resin flooring.

Install moisture barriers and ensure proper ventilation to prevent moisture-related damage.

By following these tips, you can prolong the lifespan of your resin flooring and avoid the hassle of having to remove and replace it.

Epoxy flooring is a type of resin flooring that is known for its supreme strength and long-lasting effects. It is commonly used in DIY projects and is considered one of the strongest glues available for various applications.

There are two main methods to remove epoxy flooring from a concrete slab. One option is to use a stripping solution, which involves applying a specific solution, letting it soak, and then scraping away the old epoxy. The other option is to use a light floor sander or shot blaster to strip away the epoxy layer.

To remove epoxy flooring, you may need tools such as a metal scraper, rubber gloves, an eye protection, a painter’s mask, a fiber mop, a shop vac, and potentially a light floor sander or shot blaster, depending on the method chosen.

Yes, it is possible to chemically remove epoxy from concrete floors. One method involves using a stripping solution, as mentioned earlier, which can effectively break down the epoxy layer for easier removal.

Yes, removing epoxy flooring can be a labor-intensive and time-consuming process, especially if it covers a large area. It requires careful preparation, patience, and the use of appropriate tools and equipment.

If you prefer not to remove epoxy flooring yourself, you can seek professional help from companies like Epoxy Colorado. They have expertise in applying, repairing, and replacing epoxy flooring and offer free estimates for assistance on the Colorado Front Range.

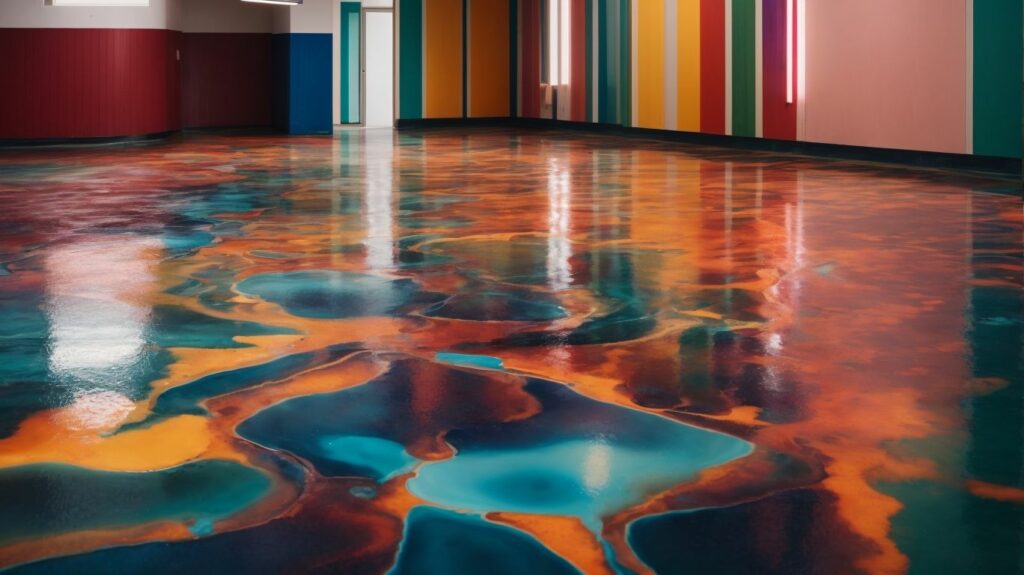

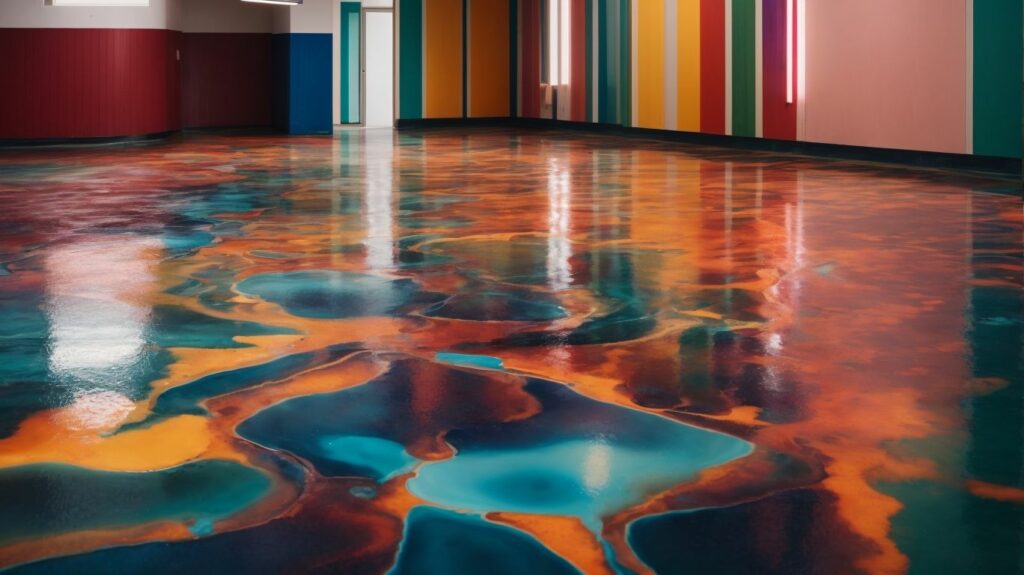

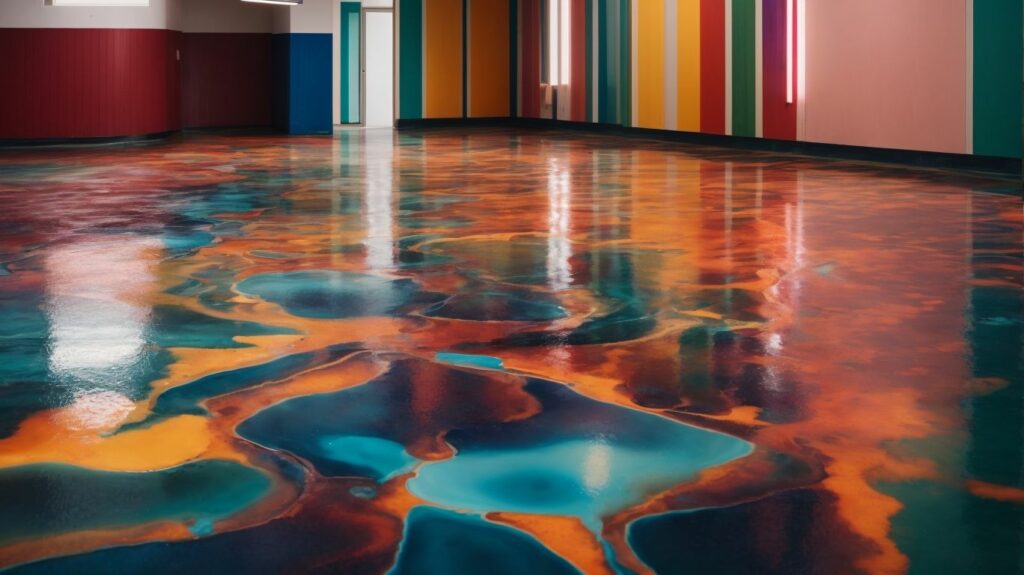

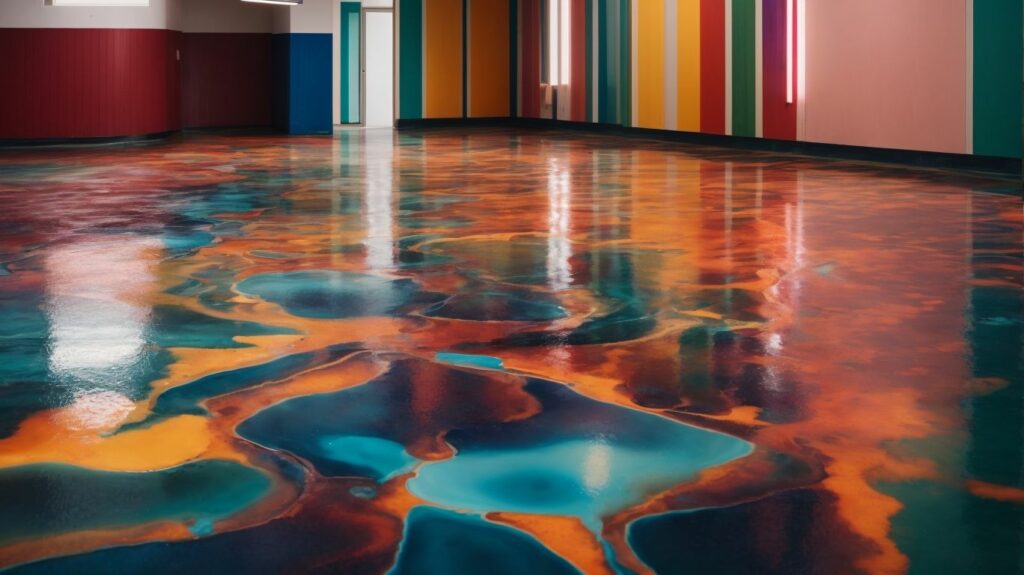

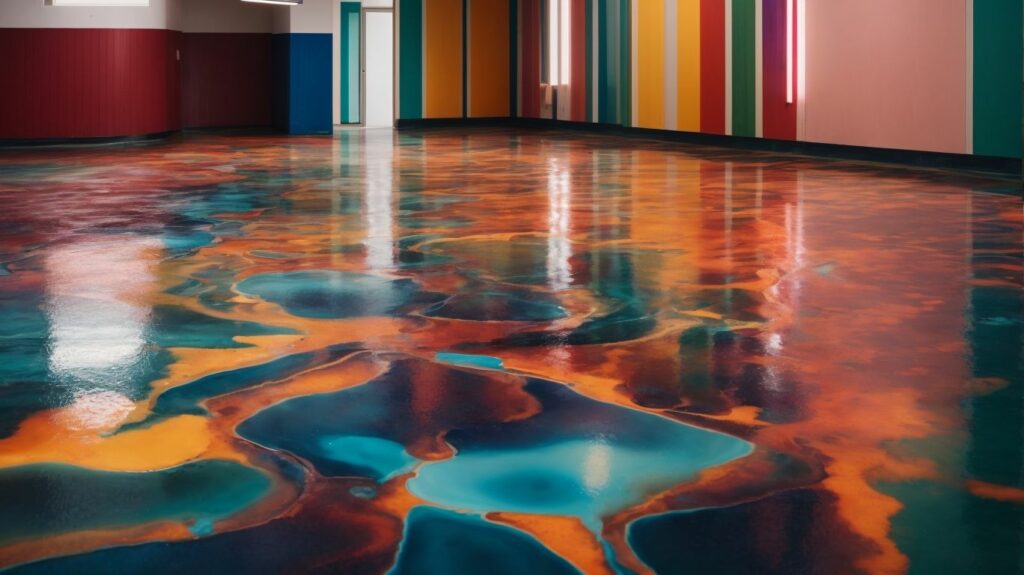

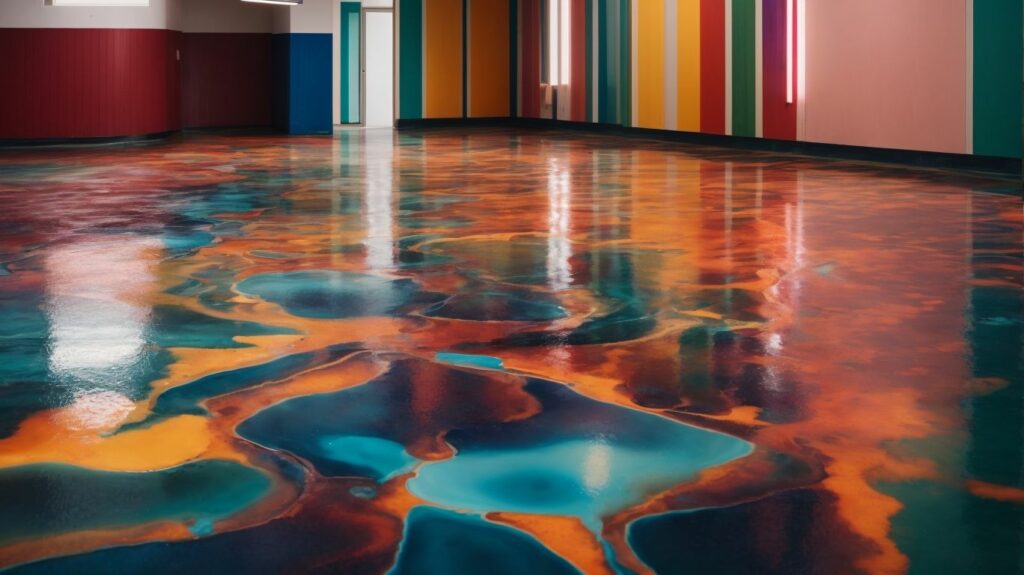

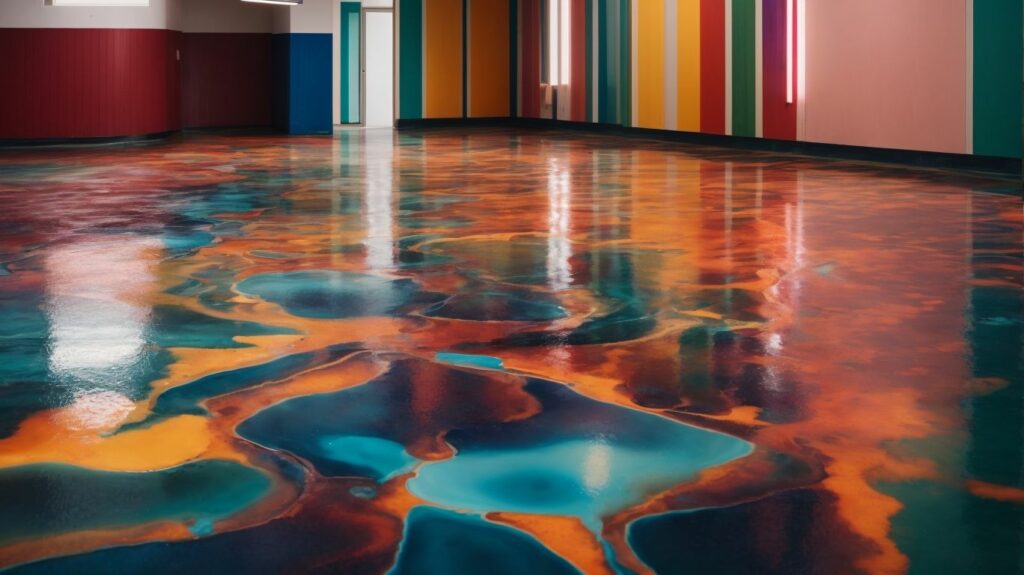

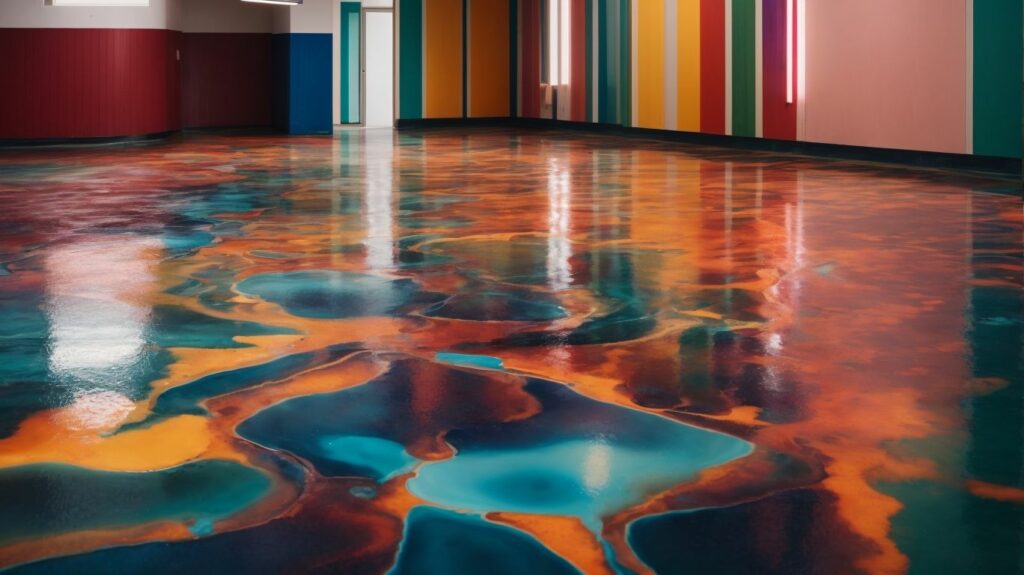

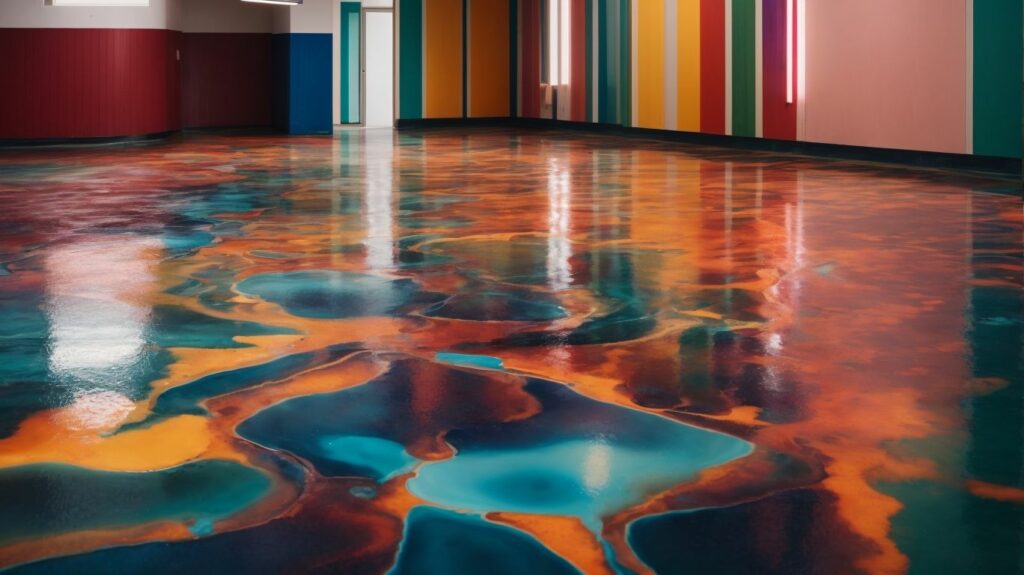

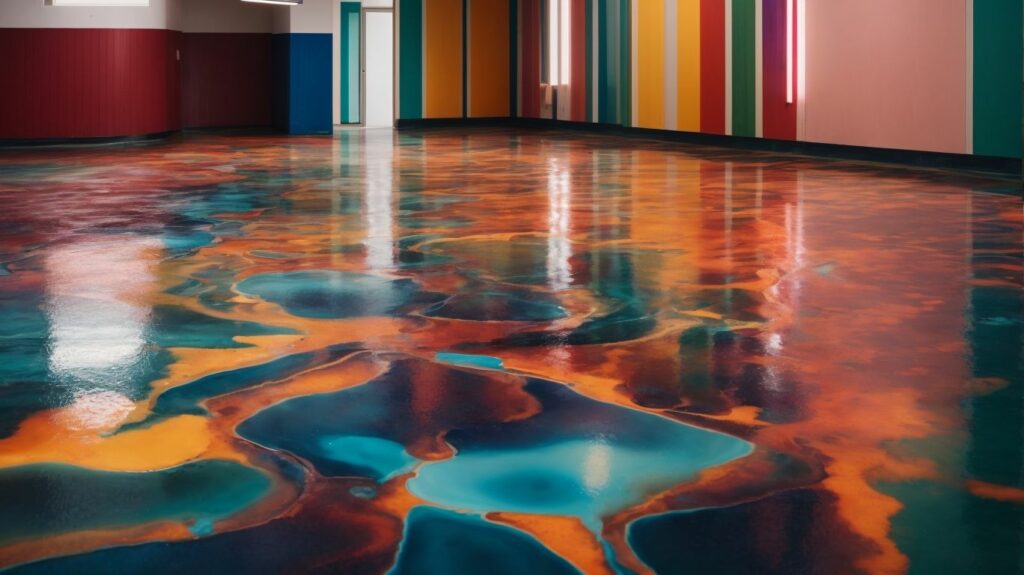

Colour Your World: Exploring the Vibrant Palette of Epoxy Floors

Epoxy floors are an incredibly versatile flooring option that offers a wide range of benefits for various spaces. Whether it’s a residential, commercial, or industrial setting, epoxy floors can transform the look and function of any space.

In residential spaces, epoxy flooring provides durable, easy-to-clean surfaces that are perfect for high-traffic areas like kitchens and bathrooms. In commercial spaces, epoxy floors offer a professional and sleek look that is ideal for offices, retail shops, and showrooms. In industrial environments, epoxy floors provide exceptional durability and resistance to chemicals, making them suitable for warehouses, factories, and manufacturing facilities.

Aside from the practical advantages, epoxy floors also come in a vibrant palette of colours, allowing for endless design possibilities. Exploring various colours of epoxy floors enables you to create a space that reflects your personal style or fits perfectly with your brand identity. Mixing and matching colours can result in unique designs, while creating patterns and designs with epoxy floors allows for even more creative expression.

The design applications of epoxy floors are vast. In homes, epoxy floors enhance the aesthetic appeal, providing a modern and polished look. In commercial spaces, they create a professional ambiance that leaves a lasting impression on clients and customers. In industrial environments, epoxy floors not only enhance safety but also improve functionality and efficiency.

However, when choosing epoxy floor colours, certain factors should be considered. Space and size play a crucial role in determining the right colour scheme, as different colours can visually impact the perception of space. Lighting and ambience should also be taken into account, as certain colours may appear differently under various lighting conditions. The overall design and theme of the space should guide the selection of epoxy floor colours to ensure a cohesive and visually pleasing result.

Epoxy floors offer versatile solutions for various spaces. Whether it’s residential, commercial, or industrial, epoxy flooring brings a vibrant palette to enhance the aesthetics and durability. Discover how epoxy floors can transform your living space into a modern haven, elevate your business setting with a polished and professional look, or provide the perfect foundation for heavy-duty industrial operations. Let’s explore the endless possibilities of epoxy flooring!

Epoxy flooring for residential spaces offers durability, easy maintenance, and a wide range of design possibilities. It is a versatile option that provides enhanced durability, easy cleaning, and design flexibility.

Pro-tip: Consider choosing a matte or satin finish for residential spaces to create a more natural and warm aesthetic.

Epoxy flooring is a versatile option for commercial spaces, offering durability, easy maintenance, and a professional appearance.

Epoxy flooring is highly versatile and can be used in various industries. In this section, we will discuss the benefits and considerations of using epoxy flooring in industrial spaces.

When choosing epoxy flooring for industrial spaces, it is important to consider the specific requirements of your industry and consult with flooring professionals to ensure you select the right type and thickness of epoxy coating.

Epoxy floors offer many benefits that make them a popular choice for both commercial and residential spaces.

Fact: Epoxy floors are also used in industrial settings due to their ability to withstand extreme temperatures and resist impact.

Get ready to explore the vibrant palette of epoxy floors. We will dive into the mesmerising world of epoxy floors and discover the wide array of colours available. We will also learn the art of mixing and matching for unique designs, unlocking the secrets of creating stunning patterns and designs using epoxy floors. So, buckle up and get ready to be amazed by the endless possibilities that await in this colourful realm.

Exploring various colours of epoxy floors offers limitless design possibilities and customisation options. Here are some examples:

True story: A homeowner wanted to transform their plain garage into a fun and vibrant space. They chose to explore various colours of epoxy floors and decided on a combination of blue and yellow for a playful look. The end result was a stunning garage that truly reflected their personality and added a unique touch to their home.

To achieve a stunning aesthetic, consider mixing and matching colours to create unique designs with epoxy floors. Here are some ways to do this:

By mixing and matching colours creatively, you can transform your space and create a one-of-a-kind epoxy floor design.

Creating patterns and designs with epoxy floors offers endless possibilities for transforming any space. Here is a step-by-step guide to achieve stunning designs:

Epoxy resin was first used in the early 20th century for electrical insulation. Its versatile properties led to its adaptation in various industries, including flooring. Today, epoxy floors are not only practical but also offer a plethora of aesthetic possibilities to elevate any space’s design. Whether it’s a residential, commercial, or industrial area, epoxy floors are a stunning choice for creating patterns and designs that stand out.

Discover the captivating world of the design applications of epoxy floors. Each sub-section of this section will unveil the unique ways in which epoxy floors can transform various settings, from enhancing the aesthetic appeal of homes to creating a professional and polished look in commercial spaces, and improving safety and functionality in industrial environments. Prepare to be inspired by the vibrant palette and dynamic potential of epoxy floors.

Enhancing the aesthetic appeal of your home with epoxy floors can be achieved through careful design choices and consideration of your space and style preferences. Here are some factors to consider when enhancing the aesthetic appeal of your home using epoxy floors:

To achieve a professional look in commercial spaces with epoxy floors, there are several steps you can follow:

In a real-life example, a local law firm transformed their office with epoxy floors. By following these steps, they achieved a professional and upscale ambiance that impressed clients and created a more productive work environment. The sleek and glossy floors added a touch of sophistication, while the seamless surface made maintenance a breeze.

Enhancing safety and functionality in industrial environments is essential for maintaining a productive and secure workspace. Here are some ways in which epoxy floors contribute to this goal:

Fact: According to a study published in the Journal of Safety Research, slip-resistant flooring, such as epoxy floors, can reduce slip and fall accidents in industrial environments by up to 90%.

Factors to Consider When Choosing Epoxy Floor Colours

When choosing epoxy floor colours, there are several important factors to consider. These factors can greatly influence your decision and help you create the perfect colour scheme for your space. Evaluating the size and layout of the area, as well as considering lighting and ambience, are all essential elements to take into account. Additionally, design and theme considerations allow you to incorporate your own personal style into the epoxy flooring. Join us as we explore these essential factors that will guide you in choosing the ideal colours for your epoxy floors, bringing your space to life.

When considering the space and size for choosing epoxy floor colours, it is important to take into account certain factors.

| Factor | Consideration |

| 1. Space | Small spaces benefit from lighter colours as they create an illusion of more space. In larger areas, darker colours can add depth and richness. |

| 2. Size | In narrow spaces, using lighter colours on the walls and darker colours on the floor can create a wider and more expansive feel. In larger areas, bold and vibrant colours can make a statement. |

To make the most of your epoxy floor colour choices, consider the dimensions and layout of the space to achieve the desired effect. Experiment with different colour combinations and consult with professionals for expert advice.

When it comes to selecting epoxy floor colours, considering lighting and ambience is crucial in order to create the desired atmosphere in your space. Here are some factors to keep in mind:

Incorporating the right lighting and ambience into your epoxy floor colour choices can transform your space and create a visually appealing and inviting atmosphere.

A restaurant owner once used warm-toned epoxy floor colours combined with soft lighting to create a cozy and intimate ambience. Customers praised the inviting atmosphere and found themselves staying longer, leading to an increase in customer satisfaction and repeat visits.

When considering epoxy floor colours, it is crucial to take into account the design and theme of your space. There are several factors to consider:

Epoxy garage floor coating offers a wide range of colors, including bold statement hues, subtle neutrals, and even iridescent effects. Homeowners in Houston can choose from various shades to create their desired aesthetic and make a lasting impression in their garage.

Epoxy garage floor coating can achieve a speckled appearance by adding epoxy flakes during the application process. These flakes come in different colors and sizes, providing a unique and transformative look to the floor.

Epoxy offers practical advantages for garage flooring. It provides a highly durable finish that can withstand heavy foot traffic and resist oil stains, hot tire pickup, and transmission fluid. The hard surface and nonporous nature of epoxy make it easy to sweep and maintain, reducing overall maintenance costs.

Yes, epoxy flooring is suitable for both commercial and industrial use. Its industrial strength layer provides long-lasting protection, making it ideal for high-traffic areas, large machinery, and humidity-prone environments. Epoxy also offers a lustrous finish that enhances visibility and creates a professional and clean aesthetic.

Users can manage their cookie settings and personalize their advertising experience on Facebook or Meta products. By accessing their account settings, they can control the use of optional cookies, review and change their advertising preferences, and choose which information is used for relevant ads. Detailed information about cookies and their use can be found in the respective privacy policies of Facebook and Meta.

Yes, Meta Audience Network enables advertisers to display relevant ads in apps and websites outside of Meta’s products. This network expands the reach of advertisements, allowing businesses to connect with users beyond the Meta ecosystem. Users can view their activities outside of Facebook, including interactions with companies and organizations.

html

Mastering the art of epoxy flooring requires careful planning and execution to ensure a successful installation. Epoxy flooring is a highly durable and versatile option that offers long-lasting protection and an attractive finish. Understanding the key aspects of epoxy flooring and following the right techniques are essential for achieving the desired results.

Before diving into the installation process, it is crucial to grasp the basics of epoxy flooring. Epoxy flooring is a type of resinous flooring system that consists of a two-part mixture, including a resin and a hardener. When combined, these two components chemically react to form a rigid, durable, and resistant surface that can withstand heavy foot traffic, impacts, stains, and chemicals.

There are several reasons why epoxy flooring is a popular choice for various applications. The seamless finish, high-gloss appearance, and availability of different colors and patterns contribute to its aesthetic appeal. Epoxy flooring offers excellent durability, easy maintenance, and resistance to abrasion, moisture, and chemicals. These qualities make it suitable for a wide range of settings, including residential garages, commercial facilities, warehouses, and industrial spaces.

Now that we have a brief understanding of epoxy flooring, let’s delve into the tips that will help you successfully install this resilient flooring option. The installation process begins with thorough preparation, and assessing the substrate is a crucial step. Proper surface preparation, including cleaning and repairing cracks and imperfections, ensures the epoxy adheres well and provides a smooth finish.

To execute a flawless epoxy flooring installation, you will need the right tools and materials. Essential tools for epoxy flooring include a power drill, epoxy mixing paddle, roller frames, spike shoes, and squeegees. Choosing the right epoxy products, such as the appropriate resin and hardener, as well as any additives or decorative elements, is equally important to achieve the desired outcome.

Following a step-by-step guide is crucial during the installation process. This includes cleaning the surface, priming the substrate, properly mixing and applying the epoxy resin, spreading the mixture evenly, and adding texture or decorative elements as desired. Understanding the curing and drying time is essential for achieving the desired hardness and durability of the epoxy flooring.

Inevitably, challenges may arise during the installation process. It is important to be prepared to troubleshoot common issues such as bubbles or pinholes, uneven coatings, and peeling or delamination. Understanding how to address these issues promptly can help salvage the installation and ensure a high-quality final result.

Finally, maintaining and extending the lifespan of your epoxy flooring requires regular cleaning and maintenance. Implementing protective measures in heavy traffic areas, such as installing mats or applying additional topcoats, can further protect the epoxy surface from wear and tear.

By following these top tips and techniques, you can master the art of epoxy flooring and achieve a successful installation that not only enhances the aesthetic appeal of your space but also provides long-lasting durability and protection.

Understanding Epoxy Flooring

Epoxy flooring is a combination of epoxy resin and hardener, creating a strong and durable surface. It is versatile and suitable for various applications, including residential, commercial, and industrial settings. It provides excellent resistance to chemicals, stains, and abrasions, and is also easy to clean and maintain, making it ideal for high-traffic areas. Proper surface preparation is crucial for a successful epoxy flooring installation. This includes thorough cleaning, repairing any cracks or imperfections, and ensuring a smooth and dry surface.

A homeowner wanted to transform their garage into a functional space. They chose to install epoxy flooring due to its durability and aesthetic appeal. After proper preparation, the epoxy flooring was installed flawlessly. The homeowner now enjoys a beautiful, easy-to-clean garage that withstands heavy use.

Epoxy flooring is a durable and versatile flooring option commonly used in commercial and industrial settings. It is created by combining resin and hardeners to form a strong and chemical-resistant surface. Epoxy flooring offers several benefits, including high durability, easy maintenance, and resistance to stains and chemicals. It is also customizable, allowing for various colours, patterns, and textures. In residential spaces, epoxy flooring is becoming more popular due to its aesthetic appeal and long-lasting properties. Epoxy flooring provides a reliable and attractive solution for creating a durable and functional floor surface.

A homeowner decided to install epoxy flooring in their garage to improve its appearance and functionality. They were impressed with how easy it was to clean and how resistant it was to stains and spills. The epoxy flooring also made their garage look more professional and spacious. They were so happy with the results that they decided to extend the epoxy flooring to other parts of their home, such as the basement and laundry room, to enjoy the same benefits throughout their living space.

Epoxy flooring offers a wide range of benefits that have made it a popular choice for residential and commercial spaces. There are several reasons why you should choose epoxy flooring:

In this section, we will discuss the important steps to prepare for a successful epoxy flooring installation. We will cover assessing the substrate, surface preparation, and repairing any cracks or imperfections. With expert tips and tricks, we will help you start your flooring project on the right track. Let’s begin by laying the groundwork for a stunning epoxy floor that will impress everyone.

Assessing the substrate is a critical step in the installation of epoxy flooring. It involves evaluating the condition of the surface where the epoxy will be applied. Here are some important factors to consider:

| – Surface condition: | Check for cracks, chips, or unevenness that may require repair before applying epoxy. |

| – Moisture levels: | Assess whether the substrate is dry or prone to moisture issues, as moisture can affect the adhesion of the epoxy. |

| – Porosity: | Determine if the substrate is porous or non-porous, as this will affect the type of epoxy primer and coating needed. |

| – Compatibility: | Ensure that the substrate is compatible with epoxy by checking its chemical resistance and reaction to the epoxy materials. |

By carefully assessing the substrate, you can address any issues beforehand and ensure a successful installation of epoxy flooring.

For optimal results, it is recommended to consult with a professional or follow the manufacturer’s guidelines for substrate assessment. Proper preparation will result in a durable and long-lasting epoxy floor.

The key to a successful epoxy flooring installation lies in proper surface preparation. Here are the steps to follow in preparing the surface for epoxy flooring:

To achieve the best results, it is recommended to consult the product manufacturer’s guidelines and follow their specific surface preparation instructions. Taking the time to properly prepare the surface will ensure a durable and long-lasting epoxy flooring installation.

Remember, a well-prepared surface is the foundation for a successful epoxy flooring project. Take the necessary steps to clean, repair, and prime the substrate to achieve optimal adhesion and a flawless finish. Happy epoxy flooring installation!

Repairing cracks and imperfections in epoxy flooring is essential for maintaining its durability and aesthetic appeal. Here are the steps to effectively repair cracks and imperfections:

By following these steps, you can effectively repair cracks and imperfections in your epoxy flooring, ensuring its longevity and attractiveness.

To achieve a flawless finish in epoxy flooring, it is essential to have the right tools and materials. In this section, we will discuss the necessary tools for epoxy flooring and how they can help you achieve success. We will also emphasize the importance of selecting the appropriate epoxy products to ensure a long-lasting installation. So, let’s get started and explore the key elements for successful epoxy flooring.

When it comes to epoxy flooring installation, it is crucial to have the right tools for a successful result. Here are some essential tools you’ll need for epoxy flooring:

|

With these essential tools, you will be well-equipped to tackle your epoxy flooring installation project.

Epoxy flooring has gained popularity in various industries over the years due to its durability, versatility, and aesthetic appeal. The use of epoxy dates back to the early 20th century when it was primarily used for industrial applications. Since then, advancements in technology and the development of more user-friendly formulations have made epoxy flooring accessible for residential and commercial use. Today, epoxy flooring is a popular choice for garages, warehouses, retail spaces, and even homes, providing a seamless and long-lasting flooring solution.

When selecting the appropriate epoxy products for your flooring project, it is crucial to take into account the following factors:

With these considerations in mind, you can select the appropriate epoxy products that will meet your flooring needs and provide long-lasting results.

Epoxy flooring has been used in various industrial and commercial applications for decades. Its origins can be traced back to the early 20th century when epoxy resin was first developed as a coating material. Over time, advancements in technology and formulation have led to the creation of epoxy products specifically designed for different flooring requirements. Today, epoxy flooring offers a durable, seamless, and attractive solution for a wide range of spaces, from warehouses and factories to retail stores and residential garages.

Looking to achieve a flawless epoxy flooring installation? Look no further! This step-by-step guide will take you through the process of achieving a successful epoxy flooring installation. From cleaning the surface to spreading the epoxy mixture, and even adding decorative elements, we’ll cover all the essential steps you need to know. Get ready to transform your floors and create a stunning, durable, and long-lasting epoxy finish. Let’s dive in!

To achieve a successful installation of epoxy flooring, it is crucial to clean the surface properly. Follow these steps to clean the surface before applying epoxy:

Fun Fact: Properly cleaning the surface enhances the adhesion of the epoxy coating, resulting in a more durable and long-lasting flooring solution.

Priming the substrate is an essential step in the epoxy flooring installation process as it guarantees proper adhesion and a long-lasting finish. Here are the steps involved in priming the substrate:

By properly priming the substrate, you establish a solid foundation for the epoxy coating, ensuring a smooth and durable finish.

Mixing and applying the epoxy resin is a crucial step in the installation of epoxy flooring. Here is a step-by-step guide to ensure a successful application:

Did you know? The use of epoxy resin dates back to ancient Egypt, where it was used as an adhesive in woodworking and pottery. Over time, the material evolved and is now widely used for various applications, including flooring, due to its durability and chemical resistance.

Pro-tip: To achieve a smooth and flawless finish, it is important to maintain a consistent spreading technique and work efficiently to avoid any inconsistencies in the epoxy layer.

Adding texture or decorative elements to epoxy flooring can enhance the appearance and style of any space. Here are some options to consider:

The use of decorative elements in flooring is not a recent trend. In fact, archaeological evidence suggests that ancient civilisations, such as the Egyptians and Romans, used various materials and techniques to create decorative flooring designs. These early flooring designs incorporated elements like mosaic tiles, marble patterns, and intricate geometric motifs. Today, the availability of modern materials and techniques, such as epoxy flooring, offers even more possibilities for adding texture and decorative elements to create visually stunning floors.

Curing and drying time is an essential aspect of epoxy flooring installation as it determines when the floor can be fully utilized. Here is a list of important points to consider regarding the curing and drying time of epoxy flooring:

By understanding and adhering to the recommended curing and drying time, you can ensure the longevity and durability of your epoxy flooring.

Troubleshooting Common Issues

Having trouble with your epoxy flooring? Don’t worry, we’ve got you covered! In this section, we’ll address some of the common issues that occur during epoxy flooring installations. From bubbles or pinholes to uneven coatings and peeling or delamination, we’ll provide tips and solutions to help you troubleshoot and overcome these challenges. Get ready to become an expert in epoxy flooring with our expert advice!

Dealing with bubbles or pinholes is a common issue when installing epoxy flooring. Here are some steps to effectively address this problem:

Proper Mixing: Ensure that you thoroughly mix the epoxy resin and hardener to prevent the formation of air bubbles.

Surface Preparation: Make sure the surface is clean and free from any contaminants that could cause bubbles or pinholes.

Rolling Technique: Use a roller to evenly spread the epoxy mixture, applying light pressure to release any trapped air.

Torching: After applying the epoxy, use a heat gun or torch to lightly pass over the surface to remove any remaining bubbles.

Sanding and Re-coating: If bubbles or pinholes still appear after curing, sand the surface and apply a new layer of epoxy to achieve a smooth finish.

Pro-tip: Make sure to properly prepare the surface and follow the manufacturer’s instructions for the epoxy product to prevent uneven coatings.

When addressing peeling or delamination with epoxy flooring, it is important to take prompt action to prevent further damage and maintain the longevity of the floor. Here are the steps to address this issue:

Incorporating these steps into your epoxy flooring maintenance routine will help prevent peeling or delamination and ensure a successful and long-lasting installation.

Epoxy flooring was first developed and used in the early 20th century for industrial purposes due to its durability and chemical resistance. Over time, its popularity grew, and it began to be used in commercial and residential settings. Today, epoxy flooring has become a popular choice for its aesthetic appeal, easy maintenance, and long lifespan. Its versatility and ability to withstand heavy traffic and varying conditions have made it a go-to option for countless industries and homeowners alike.

Translated text:To ensure the longevity and beauty of your epoxy flooring, it is crucial to maintain it properly. In this section, we will discuss practical tips for maintaining and extending the lifespan of your epoxy flooring. We will cover effective cleaning techniques and protective measures for high-traffic areas. Let’s explore the secrets to keeping your epoxy flooring in pristine condition, so you can enjoy its benefits for years to come!

Pro-tip: Avoid using harsh chemicals or abrasive cleaners as they can damage the epoxy surface. Regular cleaning will help maintain the shine and integrity of your epoxy flooring for years to come.

To ensure the protection of epoxy flooring in heavy traffic areas, it is important to consider implementing the following measures:

Choose high-quality epoxy products that are specifically designed for heavy use and durability.

Apply multiple coats of epoxy to provide an additional layer of protection.

Install mats or rugs in high-traffic areas to reduce wear and tear on the epoxy surface.

Maintain regular cleaning and maintenance of the epoxy floor to prevent dirt and debris from causing any damage.

Consider applying a topcoat or sealant to further enhance the resistance of the epoxy floor.

Epoxy flooring is a type of surface coating that provides a glossy and resilient finish. It has been gaining popularity in commercial, industrial, and residential settings due to its aesthetic appeal and durability.

For successful epoxy flooring installation, several specialized tools are necessary. These include shot blasters for surface cleaning and profiling, diamond grinders for leveling or removing tougher coatings, mixing drills and paddles for homogeneous epoxy preparation, squeegees and rollers for application, spike shoes for foot traffic during application, and non-skid aggregates for slip resistance.

Surface preparation is a crucial step in epoxy flooring installation. It involves the use of shot blasters to remove old coatings and contaminants, diamond grinders to smoothen irregularities, and industrial vacuums to eliminate residual dust and debris. Proper surface preparation ensures optimal adhesion and a smooth finish for the epoxy.

During epoxy flooring installation, professionals should wear protective gear such as respirators, protective eyewear, and gloves to safeguard against harmful fumes released by the epoxy. Adequate ventilation, achieved through high-quality fans and ventilation systems, is necessary in enclosed spaces to reduce fume concentrations and maintain a safe working environment.

Epoxy flooring installation requires expertise and the use of specialized equipment. Professionals have the knowledge and experience to ensure meticulous preparation, uniform application, and a flawless finish. Hiring a professional ensures that the epoxy flooring is installed correctly and provides long-lasting results.

For more detailed information about epoxy flooring equipment and its proper use, it is recommended to contact a professional in the field. They can provide expert guidance and advice tailored to specific project requirements.

DIY to the Rescue: A Step-by-Step Guide to Repairing Epoxy Flooring

Epoxy flooring is a popular choice for its numerous benefits, such as durability, easy maintenance, resistance to chemicals and stains, and enhanced safety. However, like any flooring material, epoxy floors can encounter issues over time. To help you address common problems and restore your epoxy flooring, here is a step-by-step guide.

Benefits of Epoxy Flooring

Common Issues with Epoxy Flooring

Step-by-Step Guide to Repairing Epoxy Flooring

Tips for Maintaining Epoxy Flooring

By following this guide and implementing proper maintenance practices, you can restore your epoxy flooring and ensure its longevity and visual appeal.

Looking to upgrade your flooring? Discover the incredible benefits of epoxy flooring. From unparalleled durability and easy maintenance to enhanced safety and resistance to chemicals and stains, epoxy flooring is truly a game-changer. So forget about costly replacements and join us as we explore why epoxy flooring should be your top choice. Get ready for a floor that not only looks stunning but also stands the test of time.

Durability and longevity are important factors to consider when selecting epoxy flooring. The following are some reasons why epoxy flooring is renowned for its durability and longevity:

Pro-tip: To maximise the durability and longevity of your epoxy flooring, make sure to follow the manufacturer’s maintenance guidelines and promptly address any repairs or issues that may arise.

Epoxy flooring is renowned for its easy maintenance, which is why it is a popular choice for various spaces. Here are some reasons why:

Fun Fact: With proper maintenance, epoxy coatings can last for up to 20 years or more, providing long-lasting and cost-effective flooring solutions.

Epoxy flooring offers excellent resistance to chemicals and stains, making it a popular choice for industrial and commercial settings. This type of flooring provides a protective barrier that prevents spills and stains from penetrating the surface, making it easier to clean and maintain. Here are some key benefits of epoxy flooring in terms of resistance to chemicals and stains:

True story: A manufacturing facility had epoxy flooring installed in their production area. One day, a chemical spill occurred, but thanks to the epoxy flooring’s excellent resistance to chemicals, the spill was quickly contained and cleaned up without causing any damage to the underlying concrete. The seamless and stain-resistant nature of the epoxy flooring saved the company time and money in repair and maintenance costs.

Enhancing safety is a crucial aspect of epoxy flooring. It helps prevent accidents and injuries in various settings by creating a slip-resistant surface and improving visibility. Here are some ways epoxy flooring enhances safety:

By incorporating these safety features, epoxy flooring ensures a secure environment for both employees and customers.

Dealing with common issues with epoxy flooring? Let’s address them head-on! From crack formation to bothersome bubbles and unsightly discoloration, we will explore each problem in detail and reveal the secrets to resolving them. Say goodbye to flooring headaches as we delve into practical solutions that will leave your epoxy floors looking flawless. No need to worry, we’ve got you covered throughout the entire process!

Crack formation is a common issue with epoxy flooring. It is usually caused by factors such as improper installation, poor substrate preparation, or heavy impact. To repair cracks in epoxy flooring, follow these steps: assess the damage, prepare the surface, remove the damaged coating, repair the cracks using epoxy filler, and finally apply a new epoxy coating. Regular maintenance is essential to prevent future cracks. Additionally, a true story recounts how a homeowner experienced crack formation in their garage epoxy flooring due to heavy furniture being moved. They successfully repaired it using the aforementioned steps.

Inspect the affected areas to determine the extent of the bubbles or blisters.

Thoroughly clean and prepare the surface by removing any dirt, dust, or grease.

Use appropriate tools and techniques to remove the existing epoxy coating from the affected areas.

Fix any cracks or damaged areas using epoxy crack fillers or patching compounds.

Release trapped air by carefully puncturing each bubble or blister and then leveling the surface.

If discoloration occurs, follow the manufacturer’s instructions to apply the appropriate stain or pigment.

Apply a new layer of epoxy coating, following the recommended application procedures.

To prevent bubbles or blistering in the future, ensure proper surface preparation, use high-quality epoxy products, and follow the manufacturer’s guidelines closely. Regular maintenance, including cleaning and avoiding harsh chemicals, can also help maintain the integrity of the epoxy flooring.

Epoxy flooring is a common issue that can be caused by several factors. It can occur due to exposure to UV rays, chemical spills, or improper installation. To address discoloration, follow these steps:

1. Assess the damage: Determine the extent and cause of the discoloration.

2. Surface preparation: Thoroughly clean the floor to remove any dirt or debris.

3. Removing epoxy coating: Use a floor grinder or chemical stripper to remove the discoloured epoxy layer.

4. Addressing discoloration: If the discolouration is due to UV exposure, apply a UV-resistant epoxy coating to prevent future fading.

5. Applying new epoxy coating: Once the floor is prepped, apply a new layer of epoxy coating, following the manufacturer’s instructions.

Regular maintenance, including cleaning and resealing, can help prevent discoloration and keep your epoxy flooring looking its best.

In this guide, we will take you through the process of repairing epoxy flooring. We will cover every aspect of the repair process, starting from assessing the damage to applying a fresh coat of epoxy. Prepare yourself to get your hands dirty and turn your damaged epoxy flooring into a smooth and long-lasting surface. Let’s get started and learn how you can bring back the former glory of your flooring!

Assessing the damage to your epoxy flooring is an important first step in the repair process. Look for cracks, bubbles or blistering, and discolouration. Evaluate the extent of the damage to determine the appropriate repairs needed. Thoroughly inspect the affected areas and make a note of any additional issues. This assessment will guide your surface preparation and help you determine the best approach to repairing the specific damage. Remember, proper assessment is crucial for a successful epoxy flooring repair. Fun fact: Assessing the damage accurately can prevent further problems and ensure a longer lifespan for your epoxy flooring.

Before repairing epoxy flooring, it is crucial to carry out proper surface preparation to ensure successful and long-lasting results. Here is a step-by-step guide to surface preparation:

By following these steps, you will ensure that the epoxy repair adheres properly and provides a sturdy and seamless finish.

To remove epoxy coating, start by following these steps:

By following these steps, you can successfully remove epoxy coating from your floor.

To repair cracks in epoxy flooring, follow these steps:

Dealing with bubbles or blistering in epoxy flooring involves identifying the cause and taking the necessary steps to fix the problem. Here is a step-by-step guide to addressing bubbles or blistering:

True story: A homeowner noticed bubbles forming in their recently installed epoxy floor. After researching the issue, they discovered that excess moisture was the cause. They resolved it by installing a vapor barrier before reapplying the epoxy, ensuring a smooth and bubble-free surface.

To address discoloration in epoxy flooring, follow these steps:

1. Determine the cause of discoloration, such as exposure to UV rays or chemical spills.

2. Thoroughly clean the affected area using a mild detergent and water.

3. If the discoloration is a result of UV damage, consider applying a UV-resistant topcoat to prevent future colour fading.

4. For stubborn stains, use a chemical cleaner specifically designed for epoxy floors, following the manufacturer’s instructions.

5. If the discoloration persists, lightly sand the affected area to remove the top layer of epoxy and reveal a fresh surface.

6. Apply a new layer of epoxy paint or coating to restore the colour and finish of the flooring.

7. Regularly maintain the epoxy flooring by cleaning it with gentle, non-abrasive cleaners and avoiding harsh chemicals and excessive sunlight exposure to prevent further discoloration.

To apply a new epoxy coating, follow these steps:

Maintaining epoxy flooring is crucial for its longevity and appearance. Here are some tips to ensure that your epoxy flooring remains in optimal condition:

The process for creating a DIY designer epoxy resin floor involves several steps:

The necessary materials for creating a DIY designer epoxy resin floor include:

To calculate the amount of resin needed for your DIY designer epoxy resin floor, follow these steps:

When working with DIY epoxy resin flooring, it is important to take the following precautions:

DIY designer epoxy resin flooring offers several benefits, including:

The copyright for the DIY designer epoxy resin floor information belongs to Google LLC in 2023.

The durability of epoxy flooring has gained significant attention in recent years, with comparative studies shedding light on its exceptional performance. Epoxy flooring offers a range of benefits that make it a popular choice for commercial and industrial spaces. This article will explore the advantages of epoxy flooring, including its durability and longevity, chemical resistance, easy maintenance and cleaning, and its aesthetic appeal and customization options.

Comparative studies have been conducted to assess the effectiveness of epoxy flooring against other flooring options. A comprehensive analysis comparing epoxy flooring with ceramic tiles, vinyl flooring, and carpet will help determine the superiority of epoxy in terms of durability and performance. In addition, comparative studies with other coating systems like urethane and acrylic coatings will provide valuable insights into the unique qualities of epoxy flooring.

When considering epoxy flooring for a specific location, several factors need to be taken into account. Factors such as traffic and usage, installation environment, and cost and budget should be carefully considered to make an informed decision and ensure optimal performance.

Lastly, this article will cover the essential maintenance and care steps required to maintain the longevity and performance of epoxy flooring. Understanding these practices will help owners and facility managers uphold the durability and aesthetic appeal of epoxy flooring over its lifespan.

By delving into comparative studies and discussing crucial factors in choosing and maintaining epoxy flooring, this article aims to provide a comprehensive understanding of the durability and performance of epoxy flooring in various settings.

Discover the remarkable advantages of epoxy flooring that make it a popular choice among homeowners and businesses. Epoxy flooring offers unmatched durability, longevity, and exceptional chemical resistance, making it a solid foundation for any space. It requires minimal maintenance and cleaning and provides a wide range of aesthetics and customization options to suit diverse preferences. Get ready to explore the world of epoxy flooring and discover the incredible benefits it offers.

Durability and longevity are important considerations when choosing epoxy flooring. Epoxy floors are renowned for their exceptional durability, making them well-suited for high-traffic areas like warehouses and commercial spaces. With proper maintenance, epoxy floors can last for many years without the need for frequent repairs or replacement. Unlike alternative flooring options such as ceramic tiles or carpet, epoxy floors exhibit high resistance to wear and tear, staining, and damage from chemicals or heavy machinery. This durability ensures that your investment in epoxy flooring will yield long-lasting results, ultimately saving you time and money.

Chemical resistance is a major advantage of epoxy flooring, making it suitable for various industries and environments.

| Chemical | Effect on Epoxy Flooring |

| Acids | Offers high resistance, protecting against corrosion |

| Alkalis | Resistant to alkaline substances, preventing damage |

| Oils and Solvents | Tolerates exposure, minimizing staining |

Epoxy flooring is known for its easy maintenance and cleaning, making it a popular choice for various spaces. To keep epoxy floors in top condition, follow these steps:

Epoxy flooring provides a wide range of options for aesthetics and customization, making it a popular choice for both residential and commercial spaces.

To achieve the desired aesthetics and customisation in epoxy flooring, it is important to work with a professional installer who can assist in selecting the appropriate colours, patterns, and finishes to suit specific needs and preferences.

Comparative Studies: Epoxy Flooring vs Other Flooring Options

Comparing the durability of epoxy flooring with other popular flooring options is a game-changer. We will explore the details of epoxy flooring and compare it to ceramic tiles, vinyl flooring, and even carpet. Prepare yourself for some enlightening insights and find out which flooring option excels in terms of longevity, maintenance, and overall performance. No unnecessary information, only solid facts supported by comparative studies. Let us reveal the ultimate winner in the battle of the floors!

Epoxy flooring and ceramic tiles are both popular flooring options, each with their own advantages based on individual needs and preferences. When choosing between epoxy flooring and ceramic tiles, it’s important to consider the following factors:

Considering these factors will help you make an informed decision based on your specific requirements and desired outcome for your space.

Epoxy flooring has a long history of use in industrial and commercial settings due to its unmatched durability and resistance to chemicals and heavy machinery. On the other hand, ceramic tiles have been used for centuries and are valued for their beauty and longevity. Today, both epoxy flooring and ceramic tiles remain popular choices for various applications, offering different benefits that cater to different needs and design preferences.

Epoxy flooring and vinyl flooring are popular options for both residential and commercial spaces. When deciding between the two, it is important to consider the following factors:

Consider these aspects based on your specific needs and preferences to make the right choice between epoxy flooring and vinyl flooring.

Epoxy flooring and carpet are two popular flooring options, each with its own advantages and disadvantages. Here are some key points to consider:

True story: Sarah, a busy homeowner with two young children, had carpets in her living room. Despite regular cleaning, the carpets always looked dingy and stained due to spills and muddy footprints. Frustrated, Sarah decided to switch to epoxy flooring, which not only improved the aesthetics but also made cleaning a breeze. She no longer had to worry about stains and could enjoy a beautiful and low-maintenance flooring solution.

Comparative Studies: Epoxy Flooring vs Other Coating Systems

Comparing the contenders in the flooring industry, we will explore the durability of epoxy flooring through comparative studies. We will uncover the strengths and weaknesses of epoxy flooring in comparison to urethane coating and acrylic coating. Through this analysis, we aim to determine which coating system is superior in the battle of the floors.

Epoxy flooring and urethane coating are two popular options for floor coatings. When comparing the two, it is important to consider several factors:

Epoxy flooring and acrylic coating are both popular options for protecting and enhancing floors. Here is a comparison table highlighting their differences:

| Category | Epoxy Flooring | Acrylic Coating |

|---|---|---|

| Appearance | Durable and glossy finish | Semi-glossy or matte finish |

| Protection | High resistance to chemicals, impacts, and abrasions | Good resistance to mild chemicals and abrasions |

| Application | Requires professional installation due to complex preparation and curing process | Easy to apply by a DIY enthusiast |

| Durability | Long-lasting and can withstand heavy foot and vehicle traffic | Less durable, better suited for low-traffic areas |

Mike, a homeowner, wanted to upgrade his garage floor. After researching, he decided to go for epoxy flooring due to its superior durability and protection. He hired professionals to install the epoxy coating, and he was thrilled with the glossy and durable finish. Several years later, even with heavy machinery use, the epoxy flooring still looks as good as new, proving its longevity and making Mike a happy customer.

Factors to Consider when Choosing Epoxy Flooring

When selecting epoxy flooring, there are important factors that require careful consideration. We will discuss these factors to help you make an informed decision. These factors include the effects of traffic and usage, the installation environment, and your budgetary constraints. By examining these factors, we can determine which epoxy flooring option offers the greatest strength and durability for your needs. It is now time to choose the most suitable flooring option for you.

When choosing epoxy flooring, it is important to consider the traffic and usage of the space where it will be installed. This will help determine the type and thickness of epoxy coating needed for optimal performance and durability.

| Factor to Consider | Description |

| Traffic | Consider the amount of foot traffic, vehicle traffic, and the type of equipment that will be used in the space. Areas with heavy traffic may require a thicker epoxy coating and additional topcoat for added protection. |

| Usage | Think about the specific activities that will take place on the epoxy floor. Different environments have different requirements. For example, a factory or warehouse may need an epoxy floor that is resistant to chemicals, oil, and impact, while a commercial kitchen may require a floor that is slip-resistant and easy to clean. |

The installation environment is a crucial factor to consider when selecting epoxy flooring. Here are the steps to take into account:

Pro-tip: Seek advice from a professional epoxy flooring contractor to evaluate the installation environment and receive personalized recommendations based on your specific requirements.

Considering the cost and budget is crucial when choosing epoxy flooring. It is important to determine the overall cost of the flooring material, installation, and any additional features or customization options. Here is a breakdown of various factors to consider:

| Factors | Considerations |

| Traffic and Usage | Higher traffic areas may require more durable and thicker epoxy coatings, which may increase the cost. |

| Installation Environment | Factors such as temperature, humidity, and substrate condition can impact the complexity and cost of the installation. |

| Material and System Choice | Different epoxy flooring systems have varying costs, so it is important to choose one that fits within your budget without compromising on quality. |

| Additional Features and Customization | Options like decorative flakes, colours, and patterns can enhance the aesthetics but may add to the overall cost. |

Taking proper care of epoxy flooring is essential for maintaining its durability and appearance. Below are some tips for the maintenance and care of epoxy flooring:

Epoxy flooring offers a seamless and gap-free surface, making it easy to clean and maintain. It is also more durable and stain-resistant, making it suitable for high footfall areas and rooms prone to spills. On the other hand, tile flooring offers a wide range of design options and can be customized with different colors, patterns, and shapes.

Both epoxy flooring and terrazzo flooring provide a seamless finish, but terrazzo flooring combines decoration with a seamless finish. Epoxy flooring, on the other hand, offers customization options with different colors and finishes.

Durability testing for epoxy flooring includes abrasion resistance tests, impact resistance tests, and chemical resistance tests. These tests assess the flooring’s ability to withstand wear and tear, damage from heavy objects or collisions, and resistance to chemical spills and corrosive substances.

Abrasion resistance tests for epoxy flooring measure the amount of material removed from the flooring using a rotating abrasive wheel. Lower abrasion loss indicates greater durability.

Epoxy flooring is a popular choice in commercial and industrial sectors due to its durability, ease of maintenance, and resistance to harsh elements. It is suitable for various industries, including food processing plants, pharmaceutical production, printing houses, and chemical processing plants.

Slip resistance testing measures the coefficient of friction on epoxy flooring, ensuring it provides a safe and slip-resistant surface. This testing helps assess the flooring’s suitability for areas where health and safety is a concern, such as health facilities, commercial properties, military installations, and space exploration facilities.

Say Goodbye to Problems: Preventing Common Issues in Epoxy Flooring: Cracks, Bubbles, and Stains

Introduction:

Epoxy flooring offers a durable and attractive solution for various residential, commercial, and industrial spaces. However, like any other flooring option, it is not without its challenges. Understanding the common problems associated with epoxy flooring and adopting preventive measures can help maintain its integrity and longevity. In this article, we will explore the concept of epoxy flooring, the reasons behind its popularity, and the prevention tips for the common issues of cracks, bubbles, and stains. By implementing these strategies, you can say goodbye to these problems and enjoy a resilient and flawless epoxy floor.

Understanding Epoxy Flooring:

Epoxy flooring is a type of surface coating that consists of epoxy resin and a hardening agent. When applied to a prepared concrete floor, it forms a strong, seamless, and highly durable surface. Epoxy flooring offers numerous benefits such as chemical resistance, ease of maintenance, and aesthetic appeal, making it a popular choice for various settings, including garages, warehouses, hospitals, and homes.

Common Problems in Epoxy Flooring:

Despite its durability, epoxy flooring can face common issues such as cracks, bubbles, and stains. Cracks can occur due to improper surface preparation, heavy impacts, or substrate movement. Bubbles can form as a result of moisture or air trapped beneath the epoxy coating during application. Stains can occur due to chemical spills or inadequate cleaning and maintenance practices. Understanding the causes of these problems is crucial in taking preventive measures.

Prevention Tips for Cracks in Epoxy Flooring:

To prevent cracks in epoxy flooring, proper surface preparation is essential. This includes thoroughly cleaning the substrate, repairing any existing cracks or damages, and ensuring an even and stable surface. Choosing the right epoxy coating for your specific needs and applying it in ideal environmental conditions, such as suitable temperature and humidity levels, can also help prevent cracks from occurring.

Prevention Tips for Bubbles in Epoxy Flooring:

Eliminating moisture and air trapped beneath the epoxy coating is key to preventing bubbles. Proper moisture testing and addressing any underlying moisture issues before application are crucial steps. Choosing the right roller or applicator and using proper mixing and application techniques, such as backrolling, can help ensure a smooth and bubble-free epoxy surface.

Prevention Tips for Stains on Epoxy Flooring:

Regular cleaning and maintenance are essential in preventing stains on epoxy flooring. Promptly cleaning up spills, especially those involving harsh chemicals, can prevent them from penetrating the epoxy and causing permanent stains. Using appropriate cleaning products, avoiding abrasive materials, and applying protective measures to minimize spills can further protect the epoxy surface and maintain its appearance.

By following these preventive tips, you can overcome the common problems of cracks, bubbles, and stains in epoxy flooring. With proper care and maintenance, you can enjoy a beautiful, durable, and problem-free epoxy floor for years to come.

Preventing common issues in epoxy flooring is essential for maintaining a flawless and long-lasting surface. This guide unveils proven techniques to prevent cracks, bubbles, and stains. By implementing these preventive measures, you can eliminate the headaches caused by these problems and enjoy a beautiful, durable epoxy floor. Let’s explore the secrets to achieving seamless and problem-free flooring.

When it comes to epoxy flooring, it is important to understand its benefits and potential issues. This article provides an introduction to epoxy flooring by discussing its popularity and common problems that can occur. Additionally, it offers prevention tips for cracks, bubbles, and stains in epoxy flooring. To prevent cracks, it is crucial to properly prepare the surface, use the right epoxy coating, and apply the epoxy in ideal environmental conditions. Eliminating trapped moisture and air, selecting the appropriate roller or applicator, and employing proper mixing and application techniques can help avoid bubbles in the epoxy flooring. Regular cleaning and maintenance, along with the use of appropriate cleaning products and protective measures, can prevent stains on the epoxy flooring. By following these prevention tips, epoxy flooring can maintain its aesthetic appeal and provide a long-lasting finish.

Epoxy flooring is a popular choice for both residential and commercial spaces due to its durability and aesthetic appeal. Understanding epoxy flooring is crucial to ensure its correct installation and maintenance. Epoxy flooring is a combination of resin and hardener that, when applied to a surface, creates a strong and seamless finish. It is resistant to cracks, bubbles, and stains, making it ideal for high-traffic areas. Proper preparation of the surface and following the manufacturer’s instructions are essential for achieving a successful epoxy flooring installation. Regular cleaning and maintenance will help prolong the lifespan of epoxy flooring and keep it looking its best.

Epoxy flooring is a popular choice for both residential and commercial spaces in the UK due to its durability, aesthetics, and low maintenance requirements. It is a type of flooring system that consists of a combination of resin and hardener, which chemically react to create a strong and durable surface. Epoxy flooring provides a sleek and shiny finish while also acting as a moisture barrier, making it ideal for areas with regular wear or potential moisture build-up. Proper surface preparation, correct mixing and application techniques, and professional installation by experienced flooring technicians are essential to avoid common issues such as cracks, bubbles, and stains.

True story: A business owner in the UK recently decided to install epoxy flooring in their commercial space. They wanted a durable and visually appealing flooring option that could withstand heavy foot traffic. After consulting with a professional resin flooring specialist and following the recommended installation process, they were able to achieve a flawless epoxy floor that not only enhanced the aesthetic appeal of their space but also provided long-lasting durability. The business owner was extremely satisfied with the outcome and continued to receive compliments on their sleek and shiny epoxy flooring.

Epoxy flooring is popular for several reasons. Firstly, it is highly durable and resistant to wear, impact, and chemicals, making it perfect for high-traffic areas. Additionally, epoxy floors are easy to clean and maintain, requiring only regular cleaning to keep them looking their best. Furthermore, epoxy floors offer aesthetic appeal as they come in a wide range of colours and finishes, allowing for customisation and creating visually appealing spaces. Moreover, epoxy floors have a long lifespan, making them a cost-effective flooring option in the long run. Lastly, epoxy can be applied to various surfaces such as concrete, metal, and wood, making it suitable for both residential and commercial spaces.

When it comes to epoxy flooring, there are a few common problems that can occur. From cracks and bubbles to stains, these issues can be quite troublesome. In this section, we will discuss each of these problems, including their causes and potential solutions. If you want to keep your epoxy floor in perfect condition, stay with us and we will guide you on how to eliminate these issues.

Cracks in epoxy flooring can be a common problem if not properly prevented. To avoid cracks in epoxy flooring, follow these tips:

By following these prevention tips, you can ensure that your epoxy flooring remains crack-free and maintains its durability over time. Remember that seeking the help of qualified flooring technicians can help ensure the best results.

Bubbles in epoxy flooring can be unsightly and compromise the integrity of the floor. Here are some prevention tips to avoid this issue:

Properly prepare the surface by thoroughly cleaning and degreasing it.

Use the correct roller or applicator to ensure even application.

Follow the manufacturer’s guidelines for mixing and applying the epoxy.

Avoid moisture and air getting trapped under the epoxy by eliminating any sources of moisture and ensuring proper ventilation during application.

By following these tips, you can minimize the chances of bubbles forming in your epoxy flooring and achieve a smooth and professional finish.

Bubbles forming in epoxy flooring have been a common issue for many years. Contractors and DIY-ers alike have faced challenges in achieving a bubble-free surface. With advancements in epoxy technology and improved application techniques, the occurrence of bubbles has significantly reduced in modern epoxy flooring systems. Professional resin flooring specialists now have the expertise and equipment needed to prevent and address this issue, ensuring a flawless and long-lasting finish.

Stains on epoxy flooring can be unsightly and difficult to remove if not properly addressed. Here are some prevention tips to keep your epoxy floor free from stains:

Regular Cleaning and Maintenance: Clean spills promptly using a mild detergent and a soft cloth or mop.

Using Appropriate Cleaning Products: Avoid harsh chemicals that can damage or discolour the epoxy floor. Use pH-neutral cleaners recommended for epoxy surfaces.

Protective Measures to Minimise Spills: Place mats or rugs in high-traffic areas or areas prone to spills to prevent direct contact with the epoxy floor.

Fact: Did you know that epoxy flooring is known for its durability and resistance to stains, making it a popular choice for commercial and industrial spaces?

Prevention Tips for Cracks in Epoxy Flooring

Maintaining the durability and aesthetic appeal of epoxy flooring requires preventing cracks. This section explores practical tips to ensure your epoxy flooring remains crack-free. From proper surface preparation to selecting the suitable epoxy coating and applying it in ideal environmental conditions, we provide valuable insights to help you prevent cracks in your epoxy flooring. These expert tips will help you bid farewell to the headaches caused by cracked flooring.

Proper surface preparation is essential for the successful installation of epoxy flooring. Follow these steps for effective surface preparation:

Proper surface preparation has been a critical aspect of flooring installations for centuries. Ancient Romans used crushed stone and lime mortar to create durable and aesthetically pleasing surfaces. By meticulously preparing the surfaces, they were able to achieve long-lasting and beautiful floors. This practice has continued to evolve over time, with modern technologies and techniques ensuring that floors not only look good but also withstand the test of time. Today, qualified flooring technicians employ advanced methods and utilize industrial-grade equipment to ensure proper surface preparation, resulting in flawless epoxy flooring installations.

Choosing the right epoxy coating is crucial to ensure a successful and long-lasting installation of epoxy flooring. Here are the steps you should follow when selecting the appropriate epoxy coating:

Applying epoxy in ideal environmental conditions is crucial to ensure a successful and durable flooring installation.

Historically, applying epoxy in ideal environmental conditions has been essential for achieving high-quality and long-lasting epoxy flooring. In ancient Egypt, builders had to carefully choose the time of year and temperature to apply resin-based coatings to their structures. They noticed that applying epoxy during hot and humid days led to poor adhesion, while cool and dry conditions produced a flawless finish. This ancient wisdom continues to guide modern-day epoxy flooring specialists in ensuring optimal conditions for successful installations.

Prevention Tips for Bubbles in Epoxy Flooring

Achieving a flawless finish in epoxy flooring requires preventing bubbles. This section will provide the best tips to ensure bubble-free epoxy surfaces. The tips include eliminating trapped moisture and air, selecting the appropriate roller or applicator, and mastering proper mixing and application techniques. With this knowledge and skillset, you can prevent bubbles from appearing in your epoxy flooring and enjoy a smooth, seamless floor.

To eliminate moisture and air trapped under epoxy flooring, follow these steps:

Prepare the surface: Ensure the concrete floor is clean, dry, and free of any contaminants.

Apply a moisture barrier: Use a manufacturer-recommended primer or moisture-blocking system to prevent moisture vapor transmission.

Eliminate air and moisture: Use a degreasing treatment to remove any oils or residues from the surface.

Apply epoxy in correct proportions: Mix the epoxy resin and hardener in the perfect ratio recommended by the manufacturer.

Choose the right roller or applicator: Use the correct tools to apply the epoxy evenly and avoid trapping air or moisture.

Properly cure the epoxy: Allow the epoxy to cure in the recommended air temperature and humidity conditions to ensure it hardens correctly.

By following these steps, you can prevent moisture and air from becoming trapped under the epoxy, resulting in a smooth and long-lasting finish. Remember to consult a professional resin flooring specialist for expert advice and installation.

Choosing the right roller or applicator is essential for a successful epoxy flooring installation. Here are some steps to consider:

Choose an applicator based on the size and type of the area you’re coating. For large areas, use a roller, and for smaller, detailed sections, use a brush.

Select the appropriate nap length for the roller, depending on the thickness of the epoxy and the desired texture.

Ensure that the roller or brush is clean and free of any debris or loose fibers that could contaminate the epoxy.

Follow the manufacturer’s instructions for proper mixing and application techniques.

Pro-tip: For larger areas, consider using a squeegee as it allows for quick and even application of the epoxy, resulting in a smoother finish.

Proper mixing and application techniques are essential for a successful epoxy flooring installation. To achieve a smooth and durable finish, follow these steps:

Pro-tip: If you are unsure about the mixing and application process, it is recommended to consult a professional resin flooring specialist for expert guidance and a flawless finish.

When it comes to maintaining the pristine condition of your epoxy flooring and preventing stains, it is important to focus on prevention. This section provides valuable tips and tricks to help you eliminate stubborn stains on your epoxy floors. From regular cleaning and maintenance to using the appropriate cleaning products and implementing protective measures, we have all the information you need. Let’s delve into the details and explore how you can keep your epoxy flooring looking flawless and free from any issues.

Regular cleaning and maintenance are essential for preserving the quality and appearance of epoxy flooring. To ensure the longevity of your epoxy floor, follow these important steps:

Using appropriate cleaning products is essential for maintaining the longevity and appearance of epoxy flooring. To ensure proper cleaning, follow these steps:

By following these protective measures, you can minimize the risk of spills and maintain the integrity of your epoxy flooring.

Epoxy flooring problems can include peeling and blistering, discoloration and fading, cracking and chipping, uneven finish, and a slippery surface.

Peeling and blistering can be caused by improper surface preparation, not using a primer, poor quality epoxy, applying epoxy in unsuitable temperatures, humidity problems, incorrect preparation of the epoxy mixture, and not allowing the epoxy to cure properly.

To prevent peeling and blistering in epoxy floors, it is important to thoroughly clean the surface, use a manufacturer-recommended primer, ensure proper surface preparation, use high-quality epoxy products, apply epoxy in suitable temperatures, address humidity issues, prepare the epoxy mixture correctly, and allow the epoxy to cure properly.

An uneven finish in epoxy flooring can be caused by improper surface preparation, improper installation, inconsistent application, or the use of low-quality epoxy products.

To avoid an uneven finish in epoxy flooring, it is important to properly prepare the surface, use professional flooring services, ensure consistent application, and choose high-quality epoxy products.

Epoxy flooring enhances safety by addressing moisture and humidity issues, implementing proper maintenance and care, and adding non-slip agents to reduce the risk of accidents.