20+ Years Experience

Specialist Resin Flooring Installers

Enquire Today For A Free No Obligation Quote

Cracking the Code: Everything You Need to Know About Epoxy Resin Flooring

Epoxy resin flooring is a versatile and durable flooring solution that has gained popularity in various industries. It is a type of flooring that uses a combination of epoxy resin and hardening agents to create a strong, seamless, and glossy surface. This type of flooring is commonly used in commercial and industrial settings, as well as in residential spaces, healthcare facilities, and educational institutions.

The benefits of epoxy resin flooring are numerous. It offers exceptional durability and strength, making it resistant to heavy foot traffic and impact. It provides excellent chemical and stain resistance, ensuring that the flooring remains unaffected by spills and chemicals. Epoxy resin flooring is also easy to maintain and clean, making it a practical choice for busy environments.

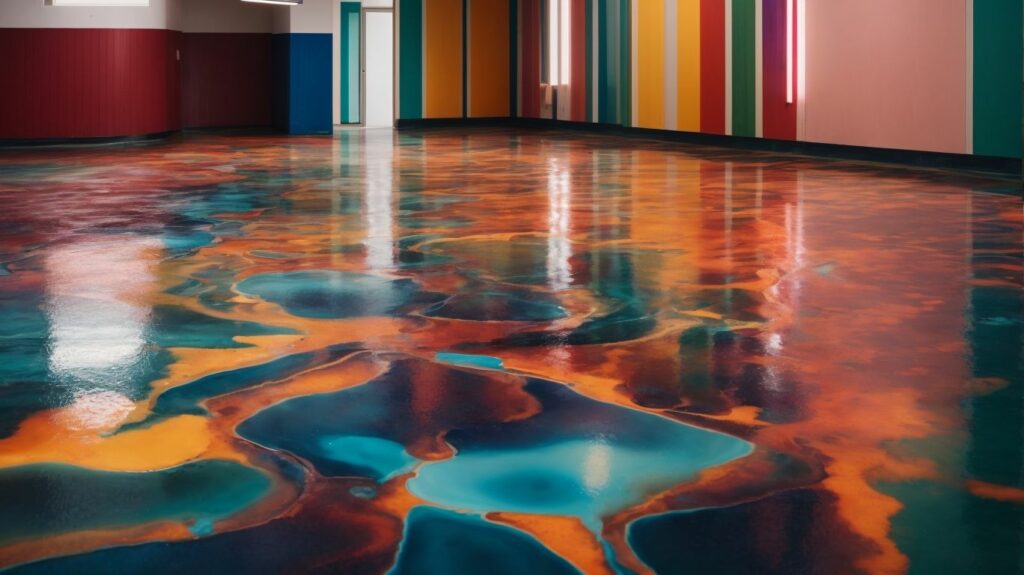

In terms of appearance, epoxy resin flooring offers aesthetic appeal and customization options. It can be applied with different colors, patterns, and textures, allowing for a personalized and visually pleasing finish.

The installation process of epoxy resin flooring involves surface preparation, mixing and application of the epoxy resin, and curing and drying time. Proper maintenance is essential to ensure the longevity of the flooring. Regular cleaning, avoiding harsh chemicals, and addressing any issues promptly are key to keeping the epoxy resin floors in optimal condition.

Despite its durability, certain issues can arise with epoxy resin flooring. Cracks and chips may occur due to heavy objects or improper installation. Yellowing or discoloration can also happen over time, especially when exposed to excessive sunlight. Understanding these common issues and troubleshooting methods is crucial for maintaining the quality and appearance of epoxy resin flooring.

Epoxy resin flooring is a surface coating commonly used in commercial and industrial settings. It is a durable and long-lasting flooring solution that provides a seamless and glossy finish. This flooring is made by mixing epoxy resin with a hardener, resulting in a chemical reaction that creates a strong and resilient material. Epoxy resin flooring is renowned for its resistance to chemicals, stains, and abrasions, making it an ideal choice for high-traffic areas. It can be customized with various colours and textures to suit specific design preferences.

Epoxy resin flooring works by combining two components, epoxy resin and a hardener, which chemically react to form a strong, durable, and seamless surface. This reaction creates a chemically resistant and high-performance flooring system that can withstand heavy traffic, impact, and chemicals. The epoxy resin and hardener mixture is applied to a prepared substrate, such as a concrete floor, and it then cures and hardens over time to create a solid and smooth surface. This flooring system is popular due to its excellent adhesion, versatility, and ability to be customized with different colours, patterns, and textures. Fact: Epoxy resin flooring can handle heavy loads, making it suitable for industrial and commercial settings.

Epoxy resin flooring is popular due to its durability and strength, making it suitable for high-traffic areas. It also provides chemical and stain resistance, making it ideal for industrial and commercial settings. Additionally, epoxy resin flooring is easy to maintain and clean, saving time and effort. It offers aesthetic appeal and customization options, allowing for creative designs. Moreover, epoxy resin flooring is versatile and can be used in various applications such as residential spaces, healthcare facilities, and educational institutions. Its popularity stems from its exceptional performance and versatility in different settings.

True story: Sarah, a small business owner, installed epoxy resin flooring in her retail store. The flooring not only withstood heavy foot traffic but also enhanced the store’s ambiance with its glossy and seamless finish. Customers were impressed by the durability and cleanliness of the flooring, leading to positive reviews and increased footfall. Sarah‘s decision to choose epoxy resin flooring proved to be a smart investment that contributed to the success of her business.

Get ready to experience the many perks of epoxy resin flooring! This type of flooring offers unbeatable durability and strength, as well as easy maintenance and cleaning. It provides exceptional resistance to chemicals and stains, and also allows for endless aesthetic appeal and customization options. Say goodbye to mundane floors and say hello to the benefits of epoxy resin flooring!

Durability and strength are key advantages of epoxy resin flooring, making it a preferred choice for various applications.

| 1. Durability | Epoxy resin flooring is highly durable, with the ability to withstand heavy traffic and impact. It can resist scratches, abrasions, and dents, ensuring a long-lasting surface. |

| 2. Strength | Epoxy resin flooring has exceptional strength, making it resistant to cracking, peeling, and chipping. It can handle the weight of heavy machinery and equipment without compromising its integrity. |

Considering these qualities, epoxy resin flooring is ideal for industries, warehouses, garages, and other high-traffic areas where durability and strength are crucial.

If you’re looking for flooring that can withstand the test of time and provide a strong foundation, epoxy resin flooring is the perfect choice. Its durability and strength will ensure a long-lasting and resilient surface for your space.

Epoxy resin flooring provides excellent chemical and stain resistance, making it a popular choice in a variety of settings. This feature protects the floor from spills, stains, and chemical exposure, ensuring its durability. The surface is non-porous, preventing liquids from penetrating the material and causing damage. Maintenance is easy, requiring simple cleaning to keep the floor looking pristine. With epoxy resin flooring, you can enjoy the benefits of a durable and visually appealing floor that can withstand harsh chemicals and stains, making it ideal for commercial, industrial, residential, and healthcare facilities.

| Benefits | Applications | Installation Process |

| 1. Durability and Strength | 1. Commercial and Industrial Settings | 1. Surface Preparation |

| 2. Chemical and Stain Resistance | 2. Residential Spaces | 2. Mixing and Application of Epoxy Resin |

| 3. Easy Maintenance and Cleaning | 3. Healthcare Facilities | 3. Curing and Drying Time |

| 4. Aesthetic Appeal and Customization Options | 4. Educational Institutions |

Epoxy resin flooring is renowned for its easy maintenance and cleaning. Let’s delve into the details:

When it comes to epoxy resin flooring, one of its main advantages is its aesthetic appeal and customization options. Epoxy resin flooring allows you to create a floor that is unique and visually pleasing, tailored to your style and preferences. Here are some ways to personalize your epoxy resin floor:

One homeowner wanted to transform their basement into a beach-themed space. They decided to install an epoxy resin floor in shades of blue with a glossy finish, and they added seashell and wave patterns. The end result was a stunning and unique floor that made them feel like they were in a coastal paradise every time they entered their basement.

Unlock the immense potential of epoxy resin flooring as we explore its diverse applications. This section covers the various ways in which epoxy resin flooring can be used in commercial and industrial settings, residential spaces, healthcare facilities, and educational institutions. Discover how epoxy resin flooring revolutionizes these environments by providing durability, aesthetics, and functionality. Explore how this versatile flooring solution enhances workplaces, homes, and public spaces, creating a solid foundation for success, comfort, and safety.

Choosing epoxy resin flooring for commercial and industrial settings offers several advantages in terms of durability, maintenance, and customization options. Here are some important points to consider:

In commercial and industrial settings, epoxy resin flooring is commonly used in warehouses, factories, laboratories, hospitals, and retail stores, among others. Its versatility and durability make it a preferred choice for areas that experience high traffic, heavy machinery, and potential chemical spills.

Epoxy resin flooring is a versatile option for residential spaces, offering a range of benefits:

Healthcare facilities greatly benefit from epoxy resin flooring due to its durability, chemical resistance, and easy maintenance. These floors can withstand heavy foot traffic, spills, and sanitizing chemicals, making them ideal for hospitals, clinics, and laboratories. Epoxy resin flooring also provides a seamless and non-porous surface, preventing the growth of bacteria and fungi. It can be customized to meet the specific needs of healthcare environments, such as anti-slip properties and hygienic coatings. Epoxy resin flooring in healthcare facilities ensures a clean, safe, and long-lasting flooring solution.

Epoxy resin flooring provides numerous benefits for educational institutions.

Consider epoxy resin flooring for educational institutions to enhance both durability and aesthetics. This flooring option provides a functional and visually appealing solution that can withstand the daily demands of an educational environment.

To ensure a successful installation of epoxy resin flooring, it is crucial to follow the correct process. In this section, we will discuss the steps involved in the installation process. From preparing the surface to properly mixing and applying the epoxy resin, and finally allowing it to cure and dry, we will break down each sub-section. Let’s delve into the details of epoxy resin flooring installation!

Before installing epoxy resin flooring, it is essential to carry out proper surface preparation to ensure a successful and long-lasting application. The following steps are involved in surface preparation for epoxy resin flooring:

By following these surface preparation steps, you can ensure that your epoxy resin flooring adheres properly and provides the desired functionality and aesthetic appeal. Remember to consult the manufacturer’s guidelines and seek professional assistance if needed.

Mixing and applying epoxy resin is a crucial step in the installation process. The following steps should be followed:

It is important to wear protective gear and work in a well-ventilated area when mixing and applying epoxy resin.

The curing and drying time of epoxy resin flooring is an important factor to consider during the installation process. It determines how long it will take for the epoxy resin to fully harden and be ready for use. The time required for curing and drying can vary depending on factors such as temperature and humidity levels. Typically, epoxy resin flooring takes around 24 to 72 hours to fully cure and dry. During this time, it is important to avoid walking or placing heavy objects on the surface to ensure proper bonding. Following the recommended curing and drying time will result in a durable and long-lasting epoxy resin floor.

To ensure the maintenance and longevity of epoxy resin flooring, there are several key factors to consider:

1. Regular Cleaning: It is important to sweep or vacuum the floor regularly in order to remove dirt and debris. Additionally, it is recommended to clean the floor with a non-abrasive, pH-neutral cleaner to avoid any potential damage to the flooring.

2. Protective Measures: To prevent dirt and moisture from being tracked onto the floor, it is advised to place mats or rugs at entryways. Furthermore, using furniture pads can help prevent scratches and dents on the floor.

3. Avoid Harsh Chemicals: It is crucial to avoid using harsh chemicals as they can cause damage to the epoxy coating. It is best to use only the recommended cleaning solutions and to be cautious of any spills or leaks of corrosive substances.

4. Periodic Maintenance: Depending on the level of foot traffic, it may be necessary to recoat the epoxy floor every few years in order to maintain its appearance and durability.

Fact: A properly maintained epoxy resin floor can last up to 20 years or even longer, making it an incredibly durable and cost-effective flooring option.

Proper maintenance of epoxy resin floors is essential to ensure their longevity and performance. To properly maintain epoxy resin floors, follow these steps:

It is important to note that epoxy resin floors are highly resistant to chemicals and stains, making them an ideal choice for industrial and commercial settings.

Factors that affect the lifespan of epoxy resin flooring include the quality of installation, environmental conditions, foot traffic, maintenance, and chemical exposure. Proper surface preparation and application techniques are important for ensuring longevity. Extreme temperatures, humidity, and exposure to UV radiation can degrade the flooring. Heavy usage can wear down the epoxy coating over time. Regular cleaning, the use of non-abrasive cleaners, and prompt repairs are essential for prolonging the lifespan. Harsh chemicals or solvents can deteriorate the epoxy surface. To maximize the lifespan of epoxy resin flooring, it is advisable to work with experienced professionals, follow maintenance guidelines, and proactively address any issues that arise.

Dealing with epoxy resin flooring can be a rewarding experience, but sometimes things don’t go as planned. This section delves into the common issues and troubleshooting techniques that can assist you in maintaining a flawless epoxy resin floor. From cracks and chips to yellowing or discoloration, we provide solutions for these challenges. So, let’s get to work and address these issues for a flawless and long-lasting epoxy resin flooring.

Cracks and chips are common issues that can occur in epoxy resin flooring. However, they can be easily addressed and repaired. Here are the steps to troubleshoot and fix cracks and chips:

By following these steps, you can effectively address and fix cracks and chips in your epoxy resin flooring, ensuring its longevity and maintaining its aesthetic appeal.

Yellowing or discolouration is a common issue that can occur with epoxy resin flooring. It can be caused by factors such as exposure to UV rays, high temperatures, or chemical reactions. To prevent yellowing or discolouration, it is important to choose high-quality epoxy resin products that have UV inhibitors and are resistant to yellowing. Proper maintenance and cleaning are also crucial for maintaining the floor’s appearance. Regularly cleaning the floor with non-abrasive cleaners and avoiding the use of harsh chemicals can help preserve its colour and prevent discolouration. If yellowing or discolouration does occur, it may be necessary to seek professional assistance for troubleshooting and repairs.

The performance requirements for resin flooring include mechanical qualities, dimensional stability, chemical and heat resistance, and low shrinkage. These factors contribute to the durability and longevity of the flooring.

No, currently there are no universally agreed European or International Standards for resin flooring products and systems. However, the British Standard BS 8204 provides recommendations for the design and installation of synthetic resin flooring, and the Code of Practise produced by British Standards is commonly used as a basis for resin floor classification.

Resin flooring products and systems are classified into different types based on their thickness and build-up. These types range from floor seals and coatings to multi-layer flooring systems. The classification helps in determining the suitability of the flooring for different applications.

Epoxy floor coatings offer numerous advantages including high bonding strength, resistance to wear and tear, heat resistance, dimensional stability, and low shrinkage. Additionally, epoxy flooring is customizable with different pigments, colored quartz, vinyl shavings, and emulsifiers to achieve desired aesthetics.

Epoxy flooring is known for its longevity and durability. It provides a hard and glossy finish that can withstand heavy foot traffic and is resistant to wear and tear. With proper installation and maintenance, epoxy flooring can last for many years.

To compare prices and find the best deal for your epoxy flooring project, it is recommended to gather multiple quotes from different suppliers and contractors. Comparing prices, materials classifications, and performance requirements specified in the quotes will help you make an informed decision and get the best value for your investment.

We Aim To Reply To All Enquiries With-in 24-Hours