20+ Years Experience

Specialist Resin Flooring Installers

Enquire Today For A Free No Obligation Quote

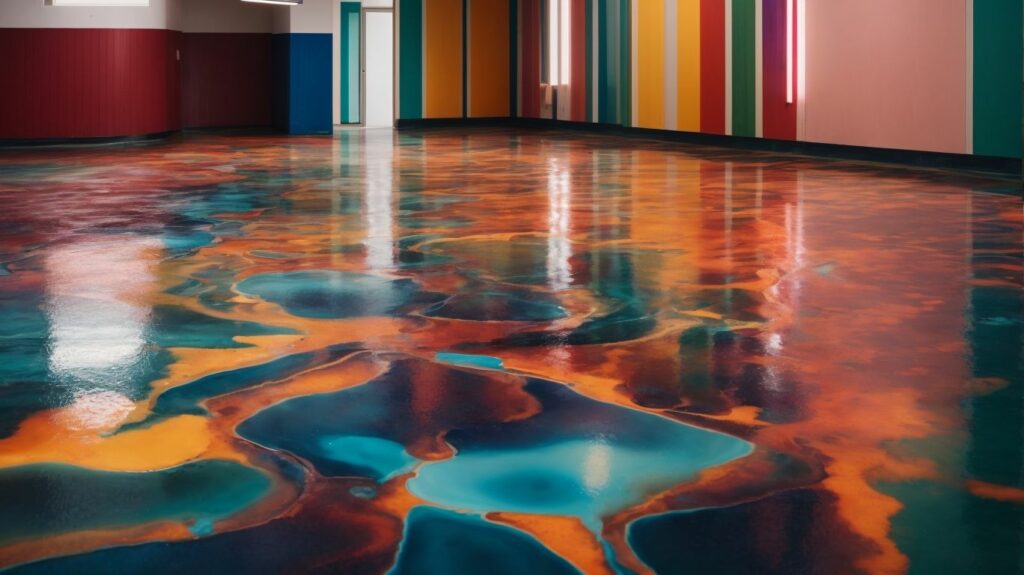

In the world of flooring options, resin flooring stands out as a versatile and durable choice. It offers a seamless and attractive finish that can be customized to suit various environments and design preferences. However, one crucial aspect of resin flooring that often poses a dilemma for individuals is finding the ideal thickness. The Goldilocks principle applies here – too little thickness may compromise durability, while too much thickness may be unnecessary and costly. So, how do you find the perfect balance for your resin flooring? Let’s explore the importance of thickness and factors to consider when choosing the thickness of resin flooring.

Resin flooring, also known as epoxy flooring, is a type of flooring system that consists of a combination of resins and hardeners. It is applied as a liquid and then cures into a solid, durable surface. Resin flooring is valued for its seamless finish, resistance to chemicals, and excellent durability. It is commonly used in commercial, industrial, and residential settings.

When it comes to resin flooring, thickness plays a significant role in determining its performance and longevity. The right thickness ensures that the flooring can withstand the demands of the environment it will be subjected to. Several factors need to be considered when choosing the thickness of resin flooring, including the application and usage, substrate condition, traffic and load requirements, and aesthetic preferences.

There are different types of resin flooring thicknesses available, each serving specific purposes. Thin resin coatings, self-leveling resin flooring, medium-build resin systems, and thick resin screeds all have their unique characteristics and benefits.

Choosing the ideal thickness for resin flooring varies depending on the environment it will be installed in. Industrial and manufacturing facilities have different requirements than commercial and retail spaces, healthcare and medical facilities, or residential and domestic applications. Understanding the specific needs of these environments will help determine the appropriate thickness.

Ultimately, finding the ideal thickness for your resin flooring involves striking the right balance between durability and cost. Assessing substrate conditions and application requirements is crucial in ensuring the longevity and performance of the flooring. Consulting with resin flooring experts and professionals can provide valuable insights and recommendations tailored to your specific needs.

To maximize the lifespan of your resin flooring, proper maintenance is essential. Regular cleaning, avoiding harsh chemicals, and addressing any damages promptly will help extend its durability and keep it looking its best.

Navigating the Goldilocks dilemma of finding the ideal thickness for your resin flooring requires careful consideration and expert guidance. By understanding the importance of thickness and the specific needs of your environment, you can make an informed decision that ensures your resin flooring is just right.

Resin flooring is a flooring system that involves the application of a resin material, typically epoxy, to create a smooth and durable finish. It is commonly used in commercial and industrial settings because of its high resistance to chemicals, abrasion, and impact. Resin flooring provides a seamless and hygienic solution that is easy to clean and maintain. It can be customised in terms of colour, texture, and thickness to meet specific design and functional requirements. Resin flooring is a popular choice for factories, warehouses, laboratories, and healthcare facilities.

A manufacturing company installed resin flooring in their production area to improve safety and efficiency. The smooth and slip-resistant surface reduced accidents caused by spills, while the chemical resistance of the resin protected the floor from damage caused by harsh industrial chemicals. The seamless nature of the flooring made it easy to clean and maintain, resulting in a more hygienic environment. The company noticed a significant improvement in productivity and employee morale due to the enhanced work environment provided by the resin flooring.

The thickness of resin flooring is of utmost importance in ensuring its performance and durability. Here are a few key reasons why thickness plays a crucial role in resin flooring:

Factors to Consider when Choosing the Thickness of Resin Flooring. When selecting the appropriate thickness for your resin flooring, various factors should be taken into account. These considerations will be explored to assist you in making an informed decision. These factors include the practical application and usage, the condition of the substrate, the specific traffic and load requirements, and the aesthetic preferences that contribute to creating the ideal resin flooring solution. Let’s delve into each aspect to determine the perfect thickness for your flooring needs.

When considering the thickness of resin flooring, the application and usage play a crucial role. The right thickness ensures optimum performance and durability.

To determine the appropriate thickness, factors like traffic, load requirements, and aesthetic preferences should be considered. For expert advice, consulting with professionals in the industry is recommended.

When choosing the thickness of resin flooring, an important factor to consider is the condition of the substrate. The surface on which the resin flooring will be applied can have a significant impact on the success and longevity of the flooring. Before determining the thickness, it is crucial to assess whether the substrate is clean, dry, and free from cracks or other damage. If the substrate is compromised, additional preparation or repair work may be required before applying the resin flooring. Failure to address the substrate condition can result in poor adhesion and issues with the flooring in the future.

When choosing the thickness of resin flooring, it is important to consider the traffic and load requirements of the space where it will be installed. Here are some factors to keep in mind:

Resin flooring with the appropriate thickness can provide high performance and withstand the demands of heavy traffic and load requirements, ensuring a durable and long-lasting solution.

Aesthetic preferences are a crucial factor to consider when choosing the thickness of resin flooring. There are several factors that should be taken into account:

Consider your aesthetic preferences and seek advice from experts to determine the ideal resin flooring thickness that matches your design vision.

Types of Resin Flooring Thickness

When it comes to resin flooring, finding the ideal thickness is akin to the Goldilocks dilemma – not excessively thin, not overly thick, but rather perfectly balanced. This section delves into the different choices available for resin flooring thickness, ranging from slender resin coatings to self-levelling systems, medium-build resin systems, and even robust resin screeds. Prepare to delve into the realm of resin flooring thickness and ascertain the most suitable option for your requirements.

Types of Resin Flooring Thickness

When it comes to resin flooring, finding the ideal thickness is akin to the Goldilocks dilemma – not excessively thin, not overly thick, but rather perfectly balanced. This section delves into the different choices available for resin flooring thickness, ranging from slender resin coatings to self-levelling systems, medium-build resin systems, and even robust resin screeds. Prepare to delve into the realm of resin flooring thickness and ascertain the most suitable option for your requirements.

Thin resin coatings are a popular choice in various environments due to their versatility and cost-effectiveness. Here are some key points to consider about thin resin coatings:

When considering thin resin coatings for your flooring, ensure that the substrate is properly prepared and in good condition. It’s also important to follow the manufacturer’s guidelines for application and maintenance to maximize the lifespan of the coating.

Remember, it’s always recommended to consult with flooring experts to determine the most suitable thickness and type of resin flooring for your specific needs. Have fun exploring the world of resin coatings for your floors!

Self-levelling resin flooring offers a durable, hygienic, and aesthetically pleasing flooring solution for a wide range of environments.

Medium-build resin systems are a popular choice for various flooring applications due to their versatility and durability. These types of resin systems are typically applied with a thickness ranging from 3 to 6 millimetres. They strike a balance between thin coatings and thick screeds, offering moderate strength and resistance to wear, impact, and chemicals. Medium-build resin systems are suitable for areas with moderate to heavy foot traffic, such as commercial and retail spaces, educational institutions, and healthcare facilities. They provide a seamless and aesthetically pleasing finish while offering sufficient protection for the underlying substrate. Medium-build resin systems are a reliable choice for achieving long-lasting and visually appealing flooring solutions.

The iconic Great Hall at Hampton Court Palace in England is known for its exquisite medium-build resin system flooring. Originally constructed in the early 1500s, the Great Hall has seen centuries of foot traffic and grand events. In order to preserve the historical integrity and enhance the durability of the flooring, a medium-build resin system was carefully selected. The installation process involved meticulous planning and skillful craftsmanship to ensure a seamless and durable finish. Today, visitors can admire the beauty of the Great Hall’s medium-build resin system flooring while experiencing a glimpse into the rich history of the palace.

Thick resin screeds are a type of resin flooring that offer enhanced durability and strength. They are commonly used in industrial and commercial environments with high traffic and heavy load requirements. Here are some key points to consider about thick resin screeds:

| Thickness: | Thick resin screeds typically have a thickness of 6mm and above. |

| Strength: | They provide excellent impact and abrasion resistance, making them suitable for areas exposed to heavy machinery or foot traffic. |

| Chemical resistance: | Thick resin screeds offer resistance against chemicals and corrosive substances, making them suitable for industries such as manufacturing and chemical processing. |

| Installation: | Proper surface preparation is crucial for applying thick resin screeds to ensure optimal adhesion and longevity. |

| Customization: | These screeds can be further customized with additional features like slip resistance and antimicrobial properties. |

When considering thick resin screeds, it is important to assess the specific requirements of your environment and consult with experts to ensure the ideal thickness for your resin flooring. Proper maintenance and regular inspections can also help extend the lifespan of your thick resin screeds.

Considering different environments is vital when it comes to addressing the Goldilocks dilemma of discovering the perfect thickness for your resin flooring. From industrial and manufacturing facilities to commercial, retail, healthcare, and residential spaces, each environment has its own distinct set of factors to consider. This section will explore these considerations, providing insight into how the thickness of resin flooring can vary depending on the specific requirements and demands of different settings.

Industrial and manufacturing facilities require durable and high-performing resin flooring options due to their harsh environments. The table below highlights key considerations for choosing the right resin flooring thickness in these facilities:

| Application and Usage | Intense heavy traffic areas require thicker resin flooring to withstand heavy machinery and foot traffic. |

| Substrate Condition | The condition of the substrate determines the needed thickness to ensure proper adhesion and structural integrity. |

| Traffic and Load Requirements | Higher traffic and load requirements demand thicker resin flooring to handle the weight and impact. |

| Aesthetic Preferences | Consider desired aesthetics, such as decorative flakes or smooth finishes, which may require specific thicknesses. |

Fact: Industrial facilities often opt for medium-build or thick resin screed systems with thicknesses ranging from 2 to 10 mm, providing excellent durability and chemical resistance.

In commercial and retail spaces, it is crucial to choose the right thickness for resin flooring. Factors to consider include the application and usage of the space, substrate condition, traffic and load requirements, and aesthetic preferences. For commercial and retail spaces, a medium-build resin system or a thick resin screed is commonly used. These types of flooring can withstand high foot traffic, heavy loads, and provide a durable and aesthetically pleasing surface. It is also important to consult with experts and consider their recommendations when determining the ideal thickness for your specific commercial or retail environment. Regular maintenance is necessary to extend the lifespan of the resin flooring in these spaces.

When selecting the thickness of resin flooring for healthcare and medical facilities, there are several factors to consider. These include determining the specific needs of the facility, such as heavy equipment or areas with high foot traffic, assessing the condition of the existing floor or substrate for proper adhesion and durability, considering the frequency and weight of equipment and tools used in the facility, and deciding on the desired appearance, whether it’s a seamless, glossy finish or a textured surface for slip resistance.

Finding the ideal thickness is crucial for balancing durability and cost. Consulting experts and following their recommendations ensures the best outcome. Regular maintenance and proper cleaning practices will extend the lifespan of the resin flooring in healthcare and medical facilities.

Resin flooring is a popular choice for residential and domestic applications due to its durability, versatility, and aesthetic appeal. When considering resin flooring for your home, there are a few key factors to keep in mind:

Pro-tip: Consult with a resin flooring expert to determine the ideal thickness for your specific residential needs, considering factors such as function, design, comfort, and maintenance.

Finding the ideal thickness for your resin flooring is similar to solving the Goldilocks dilemma: it must be just right. In this section, we will explore the delicate balance between durability and cost when determining the perfect thickness for your flooring. We will also discuss the importance of thoroughly assessing substrate and application requirements to ensure a successful outcome. Additionally, industry experts will provide their recommendations and valuable consulting on this crucial decision. Let’s now delve into the key factors involved in finding the ideal thickness for your resin flooring.

Balancing durability and cost is an important consideration when choosing the thickness of resin flooring. Striking the right balance between these two factors ensures that the flooring is long-lasting and cost-effective. Here is a table summarising the considerations for balancing durability and cost in resin flooring:

| Consideration | Importance |

| 1. Material quality | High-quality materials may initially cost more, but they offer greater durability and longevity. |

| 2. Installation expertise | Choosing experienced professionals for installation ensures proper application and maximises the durability of the resin flooring. |

| 3. Maintenance requirements | Regular maintenance and cleaning can extend the lifespan of the flooring, reducing the need for expensive repairs or replacements. |

| 4. Long-term cost analysis | Considering the overall lifespan of the flooring and potential maintenance costs can help determine the cost-effectiveness of different thickness options. |

John, a business owner, faced the dilemma of balancing durability and cost when choosing resin flooring for his warehouse. After weighing his options and consulting experts, he opted for a thicker resin screed that offered superior durability and longevity. Although it required a slightly higher upfront cost, John found that the reduced need for repairs and replacements in the long run made it a cost-effective choice. His resin flooring remained in excellent condition, withstanding heavy traffic and various loads, ensuring a safe and durable environment for his business.

Inspect the substrate: Check for any cracks, moisture, or unevenness on the existing floor.

Consider the application type: Determine the purpose of the space where the resin flooring will be installed. For example, is it a heavy traffic area or a space that requires chemical resistance?

Evaluate the environmental conditions: Take into account factors such as temperature and humidity, as they can affect the performance of the resin flooring.

Consult with experts: Seek advice from resin flooring specialists who can provide guidance based on the specific requirements of your project.

By carefully assessing the substrate and application requirements, you can ensure that the chosen thickness of the resin flooring will meet the needs of the space and provide long-lasting durability.

When choosing the thickness of resin flooring, it is important to seek expert recommendations and consulting. Experts can provide valuable insights and advice based on their knowledge and experience in the field. They can assess the specific requirements of your application, taking into consideration factors such as the type of environment, traffic and load requirements, and aesthetic preferences. By consulting with experts, you can ensure that you choose the appropriate thickness for your resin flooring, maximizing its durability and performance. Remember, expert guidance can save you time and money in the long run.

In a similar tone, there is a true story of a company that was unsure about the thickness of resin flooring to choose for their manufacturing facility. They consulted with experts who analysed their needs, including heavy machinery and high foot traffic. Based on their recommendations, the company opted for a medium-build resin system that provided the perfect balance of durability and cost-effectiveness. The experts’ insights and consulting proved invaluable, as the resin flooring has remained in excellent condition, withstanding the demands of the facility for many years.

Maintaining and extending the lifespan of resin flooring is crucial for its durability and appearance. Here are some useful tips:

Regular Cleaning: Clean the floor regularly using a mild detergent and a soft mop or cloth. Avoid using abrasive materials or harsh chemicals that may damage the surface.

Preventive Measures: Use mats or rugs in high-traffic areas to prevent excessive wear and tear. Place furniture pads or coasters underneath heavy furniture to prevent scratches and indentations.

Spills and Stains: Clean up spills immediately to prevent staining. Use a blotting motion instead of rubbing to avoid spreading the stain. For stubborn stains, refer to the manufacturer’s guidelines for proper cleaning solutions.

Routine Maintenance: Schedule periodic inspections to identify any signs of damage or wear. Address any issues promptly to prevent further damage and extend the lifespan of the flooring.

Professional Maintenance: Consider hiring a professional flooring contractor for regular maintenance tasks such as buffing, polishing, and resealing, depending on the specific requirements of your resin flooring.

The thickness of resin flooring is determined by factors such as the intended use and type of epoxy. Considerations include traffic levels, exposure to chemicals, and the condition of the concrete substrate.

For light use areas with minimal foot traffic, a thickness of less than 1mm is sufficient. Medium use areas with regular foot traffic and forklift use typically require a thickness of 2 to 4mm. Heavy use areas with constant usage, such as garages, may need a thickness of 4 to 6mm. And for very heavy use, such as outdoor spaces with extremely large loads, a thickness over 6mm is recommended.

Resin flooring, when applied at the correct thickness, provides a strong surface that can absorb shocks and prevent damage to the concrete substrate. Using high-quality materials and professional installation services further contribute to the floor’s longevity and durability.

Resin floors offer a cost-effective and flexible flooring solution suitable for various settings, including schools, airports, warehouses, and food preparation areas. They are highly durable, easy to maintain, water-resistant, and can be customized with contemporary patterns.

To specify the correct thickness for your resin floor, consider the level of use, the condition of the flooring system, and any specific requirements for the space. Consulting with professional installation services can provide guidance on selecting the appropriate depth for your project.

The cost of resin flooring installation depends on factors such as the surface area, the need for concrete substrate preparation, and any additional customization options. To determine the cost for your specific project, you can contact installation services providers for a no-obligation resin flooring cost assessment.

We Aim To Reply To All Enquiries With-in 24-Hours