20+ Years Experience

Specialist Resin Flooring Installers

Enquire Today For A Free No Obligation Quote

Mastering the Art of Resin Flooring: A Comprehensive Guide

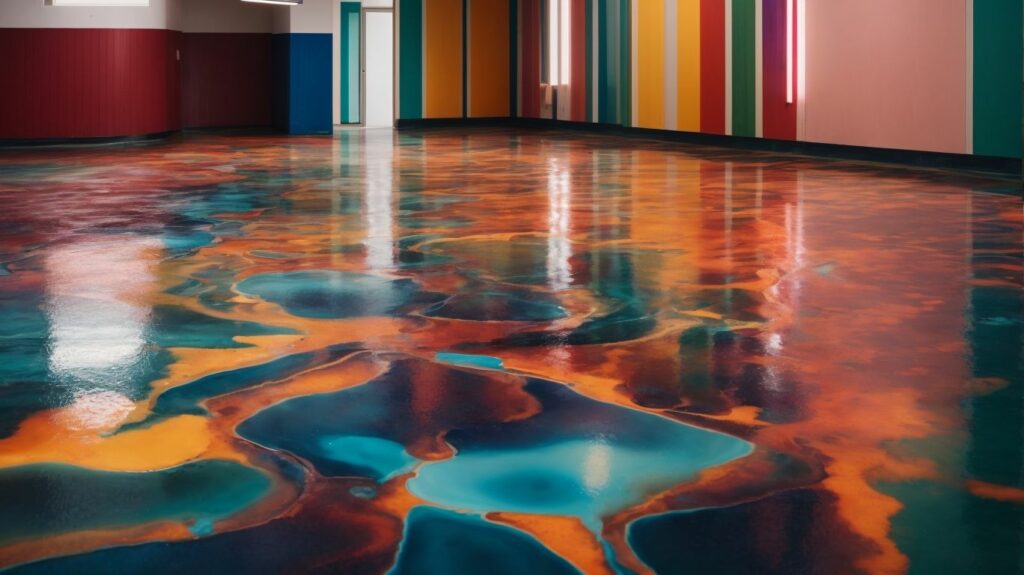

Resin flooring is a popular choice for both residential and commercial spaces due to its durability, versatility, and aesthetic appeal. This comprehensive guide aims to provide a thorough understanding of resin flooring, including its different types, advantages, installation process, maintenance, and troubleshooting.

Understanding Different Types of Resin Flooring

Resin flooring encompasses a range of materials, each with its own unique properties and characteristics. This guide will delve into the following types of resin flooring: Epoxy Resin Flooring, Polyurethane Resin Flooring, Methyl Methacrylate (MMA) Resin Flooring, and Acrylic Resin Flooring. By exploring the distinct features of each type, you can make an informed decision based on your specific requirements and preferences.

Advantages and Benefits of Resin Flooring

Resin flooring offers numerous benefits that make it an attractive option for various applications. These advantages include exceptional durability, resistance to chemicals and moisture, easy maintenance, and a wide range of design options. Understanding the benefits of resin flooring can help you determine if it is the right choice for your space.

Factors to Consider Before Installing Resin Flooring

Before embarking on a resin flooring project, there are certain factors that need to be taken into consideration. These factors include substrate preparation, traffic and usage requirements, chemical and moisture resistance, and the desired anti-slip properties. By addressing these considerations beforehand, you can ensure that your resin flooring installation meets your specific needs.

Installation Process for Resin Flooring

A proper installation process is crucial for achieving a flawless resin flooring finish. This guide will take you through the step-by-step installation process, including surface preparation, priming, mixing and application of the resin, and the application of topcoat and sealant. Following these guidelines will help you achieve a high-quality and long-lasting resin flooring system.

Maintenance and Cleaning Tips for Resin Flooring

To preserve the longevity and appearance of your resin flooring, proper maintenance and cleaning are essential. This section will provide you with valuable tips and techniques for routine cleaning, stain removal, and preventative maintenance. By implementing these practices, you can keep your resin flooring looking pristine for years to come.

Common Issues and Troubleshooting

Despite its durability, resin flooring may encounter certain issues over time. This guide will address common problems such as cracking, peeling, discolouration, and unevenness, along with troubleshooting techniques to resolve these issues effectively. Understanding how to identify and rectify these problems will help you maintain the integrity and aesthetics of your resin flooring.

By mastering the art of resin flooring through this comprehensive guide, you will be equipped with the knowledge and skills necessary to make informed decisions, achieve successful installations, and ensure the long-term performance and beauty of your resin flooring.

When it comes to understanding different types of resin flooring, it is important to explore the various options available. This section will discuss epoxy resin flooring, polyurethane resin flooring, methyl methacrylate resin flooring, and acrylic resin flooring. Each sub-section will provide information on the distinct characteristics, applications, and benefits of these resin flooring types. Prepare to delve into the captivating world of resin flooring and enhance your knowledge on this crucial aspect of interior design and construction.

Epoxy resin flooring is a popular choice for many commercial and industrial spaces due to its durability and chemical resistance. Here is a table outlining some key features of epoxy resin flooring:

| Feature | Description |

| Durability | Epoxy resin flooring is highly durable and can withstand heavy foot traffic and machinery. |

| Chemical Resistance | It has excellent resistance to a wide range of chemicals, making it suitable for areas where spills and chemical exposure are common. |

| Seamless Finish | Epoxy resin flooring creates a smooth and seamless surface, eliminating cracks and joints where dirt and bacteria can accumulate. |

| Customisation | It can be customised with different colours, patterns, and textures to create a visually appealing floor. |

| Easy Maintenance | Epoxy resin flooring is easy to clean and maintain, requiring minimal effort to keep it in good condition. |

When considering epoxy resin flooring for your space, ensure that proper surface preparation is done and that it meets your specific needs in terms of traffic, chemical resistance, moisture resistance, and anti-slip properties. Consulting with a professional in resin flooring installation is recommended to ensure a successful and long-lasting result.

Epoxy resin flooring offers numerous benefits and advantages, making it a reliable and practical choice for commercial and industrial spaces. Consider its durability, chemical resistance, seamless finish, customisation options, and easy maintenance when selecting flooring for your space. Consulting with professionals will ensure that you make the right choice for your specific needs.

Polyurethane resin flooring is a popular choice for many commercial and industrial spaces due to its durability and resistance to chemicals, abrasions, and impact. Here are some key points to consider when it comes to polyurethane resin flooring:

A manufacturing plant in the UK installed polyurethane resin flooring in their production area. Not only did it withstand heavy equipment and foot traffic, but it also provided excellent chemical resistance against the harsh substances used in their processes. The seamless and easy-to-clean surface made maintenance a breeze, contributing to a clean and hygienic workspace for their employees. The polyurethane resin flooring proved to be a durable and cost-effective solution for their industrial needs.

Methyl Methacrylate (MMA) resin flooring is a type of resin flooring that offers fast curing times and high chemical resistance. It is commonly used in environments that require a quick turnaround, such as commercial kitchens and hospitals.[1] MMA resin flooring is known for its durability and ability to withstand heavy traffic.[2] It is also resistant to staining and easy to clean, making it a popular choice for areas that require strict hygiene standards.[3] A true example of the effectiveness of MMA resin flooring is its use in a busy restaurant kitchen, where it was able to withstand constant spills and foot traffic without showing any signs of wear and tear.[4]

Acrylic resin flooring is a popular choice for various commercial and industrial applications due to its durability, versatility, and aesthetic appeal. Here are some key points to consider when it comes to acrylic resin flooring:

Resin flooring offers numerous advantages and benefits that make it a popular choice for both residential and commercial spaces.

Historically, resin flooring dates back to ancient Egypt, where it was commonly used in the construction of temples and palaces. The Egyptians recognised the durability and aesthetic appeal of resin flooring, showcasing their advanced knowledge of materials and design. Today, resin flooring continues to evolve and improve, becoming an innovative solution for modern spaces.

When it comes to resin flooring, there are important factors to consider before installation. These factors include substrate preparation, chemical resistance, moisture resistance, and anti-slip properties. Understanding these elements will help you make informed choices for your flooring needs. Let’s explore the essential factors you need to evaluate before installing resin flooring.

Substrate preparation is an important step in the installation of resin flooring. It ensures proper adhesion and a long-lasting finish. Here is a list of steps involved in substrate preparation:

Clean the surface thoroughly by removing any dirt, dust, grease, or contaminants.

Repair any cracks, holes, or uneven areas on the substrate using appropriate patching materials.

Level the surface by grinding or shot blasting to create a rough texture for better adhesion.

Etch the substrate with an acid wash or mechanical abrasion to promote bonding.

Remove any excess moisture or moisture barriers that could affect the performance of the resin flooring.

Prime the surface with a suitable primer to enhance adhesion and prevent moisture penetration.

Substrate preparation has been a vital part of flooring installation for centuries. Ancient civilizations used techniques like pounding clay or sand to create a smooth and even surface before applying their floor finishes. Over time, advancements in materials and technology have led to more efficient and effective methods of substrate preparation, ensuring durable and beautiful resin flooring installations.

When considering resin flooring, it is important to take into account the specific traffic and usage requirements of the space. This will ensure that the chosen resin flooring system is durable and able to withstand the demands of the environment.

When considering resin flooring, it is important to take into account the specific traffic and usage requirements of the space. This will ensure that the chosen resin flooring system is durable and able to withstand the demands of the environment.

Chemical resistance is an important consideration when selecting resin flooring. It determines the floor’s ability to withstand exposure to different chemicals without deteriorating. Here is a table that displays the chemical resistance of various types of resin flooring:

| Resin Flooring Type | Chemical Resistance |

| Epoxy Resin Flooring | High resistance to most chemicals, including acids and solvents. |

| Polyurethane Resin Flooring | Excellent resistance to oils, greases, and chemicals. |

| Methyl Methacrylate Resin Flooring | Good resistance to chemicals, including acids and alkalis. |

| Acrylic Resin Flooring | Moderate resistance to some chemicals. |

Fact: Epoxy resin flooring is well-known for its exceptional chemical resistance, making it a popular choice for industrial and commercial settings.

By considering these factors, you can select and install a resin flooring system that effectively resists moisture and avoids potential issues in the future.

Anti-slip properties are an important factor to consider when selecting resin flooring. Here are some key points to keep in mind:

Installing resin flooring is a crucial process that requires careful attention to detail. In this section, we will guide you through the essential steps and techniques involved in the installation process. This includes thorough surface preparation, precise resin application, and achieving a flawless finish through topcoat and sealant application. By mastering the art of resin flooring, you can transform your space into something truly stunning.

Surface preparation is an essential step in the installation of resin flooring. It ensures proper adhesion and the longevity of the flooring system. The following steps are involved in surface preparation:

Priming is a crucial step in the installation process of resin flooring. It involves applying a primer coat to the substrate before the resin is applied.

Priming serves several purposes:

To achieve proper priming, the substrate should be clean, dry, and free from any contaminants. The primer should be applied evenly using a roller or brush and allowed to cure according to the manufacturer’s instructions before proceeding with the application of the resin.

Proper priming is crucial for a successful resin flooring installation, as it promotes durability and enhances the overall performance of the floor.

The mixing and application of resin is a crucial step in the installation process of resin flooring. Here are the steps involved in this process:

Surface Preparation: Ensure that the substrate is clean, dry, and free from any contaminants.

Priming: Apply a suitable primer to enhance adhesion between the substrate and the resin.

Mixing: Follow the manufacturer’s instructions and mix the resin components thoroughly to achieve a homogeneous mixture.

Application: Use a trowel or roller to apply the resin onto the prepared surface evenly.

Topcoat and Sealant Application: Apply a topcoat to protect the resin and enhance its durability. Apply a sealant to promote resistance against chemicals and moisture.

By following these steps correctly, you can ensure a proper mixing and application process for resin flooring.

Applying a topcoat and sealant is a crucial step in the installation process of resin flooring. It helps protect the surface from wear and tear, chemicals, and moisture, ensuring longevity and durability. Here are the steps involved in topcoat and sealant application:

A company specialising in industrial floor coatings applied a topcoat and sealant to a warehouse floor. Despite the high volume of foot and vehicle traffic, the floor remained in excellent condition for years, thanks to the proper application of the topcoat and sealant. This not only saved the company money on repairs and replacement but also ensured a safe and durable working environment for their employees.

Maintenance and Cleaning Tips for Resin Flooring

To ensure that your resin flooring remains in top condition, it is crucial to perform regular maintenance and cleaning. By following these tips, you can keep your resin floors looking pristine:

Pro-tip: To prevent scratches and damage, refrain from dragging heavy furniture or sharp objects across the resin floor. By consistently maintaining and properly caring for your resin flooring, you can extend its lifespan.

Resin flooring can experience common issues that require troubleshooting in order to achieve a flawless finish. Here are some potential problems and their solutions:

The 3-day training course for mastering resin flooring lasts for a duration of three days.

No, previous experience is not required for the fast-paced 1-day course on expert techniques for creating stunning epoxy countertops.

You can cancel contracts related to resin flooring by using the provided option to terminate contracts.

High-quality work in resin flooring is guaranteed by following the guidelines and security measures provided.

The Wizard, with over 7 years of experience and numerous completed projects, is considered the best in the industry for resin flooring.

The 3-day training course provides a comprehensive understanding of epoxy flooring and the opportunity to learn directly from the industry’s best, the Wizard.

We Aim To Reply To All Enquiries With-in 24-Hours