20+ Years Experience

Specialist Resin Flooring Installers

Enquire Today For A Free No Obligation Quote

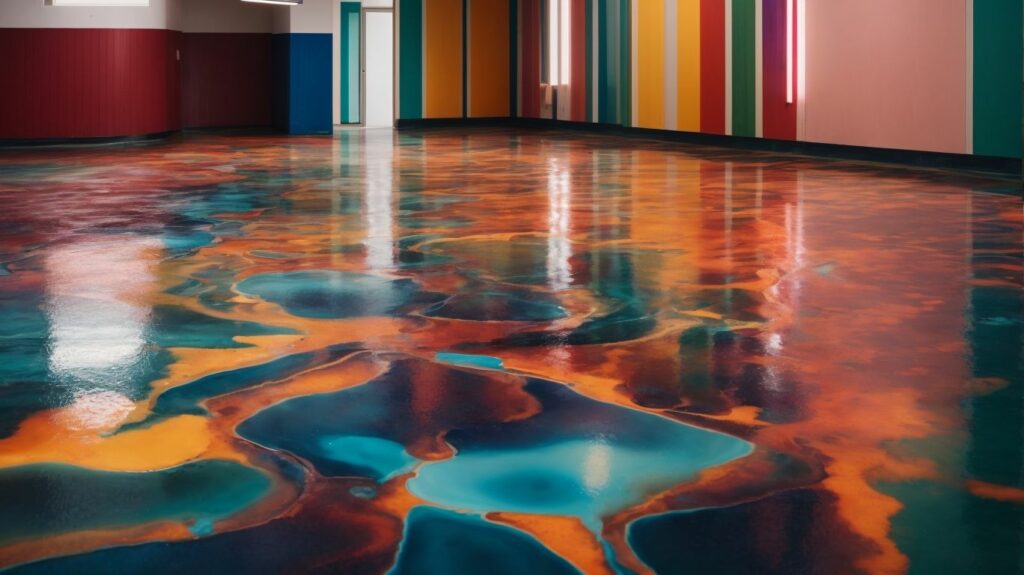

Say Goodbye to Problems: Preventing Common Issues in Epoxy Flooring: Cracks, Bubbles, and Stains

Introduction:

Epoxy flooring offers a durable and attractive solution for various residential, commercial, and industrial spaces. However, like any other flooring option, it is not without its challenges. Understanding the common problems associated with epoxy flooring and adopting preventive measures can help maintain its integrity and longevity. In this article, we will explore the concept of epoxy flooring, the reasons behind its popularity, and the prevention tips for the common issues of cracks, bubbles, and stains. By implementing these strategies, you can say goodbye to these problems and enjoy a resilient and flawless epoxy floor.

Understanding Epoxy Flooring:

Epoxy flooring is a type of surface coating that consists of epoxy resin and a hardening agent. When applied to a prepared concrete floor, it forms a strong, seamless, and highly durable surface. Epoxy flooring offers numerous benefits such as chemical resistance, ease of maintenance, and aesthetic appeal, making it a popular choice for various settings, including garages, warehouses, hospitals, and homes.

Common Problems in Epoxy Flooring:

Despite its durability, epoxy flooring can face common issues such as cracks, bubbles, and stains. Cracks can occur due to improper surface preparation, heavy impacts, or substrate movement. Bubbles can form as a result of moisture or air trapped beneath the epoxy coating during application. Stains can occur due to chemical spills or inadequate cleaning and maintenance practices. Understanding the causes of these problems is crucial in taking preventive measures.

Prevention Tips for Cracks in Epoxy Flooring:

To prevent cracks in epoxy flooring, proper surface preparation is essential. This includes thoroughly cleaning the substrate, repairing any existing cracks or damages, and ensuring an even and stable surface. Choosing the right epoxy coating for your specific needs and applying it in ideal environmental conditions, such as suitable temperature and humidity levels, can also help prevent cracks from occurring.

Prevention Tips for Bubbles in Epoxy Flooring:

Eliminating moisture and air trapped beneath the epoxy coating is key to preventing bubbles. Proper moisture testing and addressing any underlying moisture issues before application are crucial steps. Choosing the right roller or applicator and using proper mixing and application techniques, such as backrolling, can help ensure a smooth and bubble-free epoxy surface.

Prevention Tips for Stains on Epoxy Flooring:

Regular cleaning and maintenance are essential in preventing stains on epoxy flooring. Promptly cleaning up spills, especially those involving harsh chemicals, can prevent them from penetrating the epoxy and causing permanent stains. Using appropriate cleaning products, avoiding abrasive materials, and applying protective measures to minimize spills can further protect the epoxy surface and maintain its appearance.

By following these preventive tips, you can overcome the common problems of cracks, bubbles, and stains in epoxy flooring. With proper care and maintenance, you can enjoy a beautiful, durable, and problem-free epoxy floor for years to come.

Preventing common issues in epoxy flooring is essential for maintaining a flawless and long-lasting surface. This guide unveils proven techniques to prevent cracks, bubbles, and stains. By implementing these preventive measures, you can eliminate the headaches caused by these problems and enjoy a beautiful, durable epoxy floor. Let’s explore the secrets to achieving seamless and problem-free flooring.

When it comes to epoxy flooring, it is important to understand its benefits and potential issues. This article provides an introduction to epoxy flooring by discussing its popularity and common problems that can occur. Additionally, it offers prevention tips for cracks, bubbles, and stains in epoxy flooring. To prevent cracks, it is crucial to properly prepare the surface, use the right epoxy coating, and apply the epoxy in ideal environmental conditions. Eliminating trapped moisture and air, selecting the appropriate roller or applicator, and employing proper mixing and application techniques can help avoid bubbles in the epoxy flooring. Regular cleaning and maintenance, along with the use of appropriate cleaning products and protective measures, can prevent stains on the epoxy flooring. By following these prevention tips, epoxy flooring can maintain its aesthetic appeal and provide a long-lasting finish.

Epoxy flooring is a popular choice for both residential and commercial spaces due to its durability and aesthetic appeal. Understanding epoxy flooring is crucial to ensure its correct installation and maintenance. Epoxy flooring is a combination of resin and hardener that, when applied to a surface, creates a strong and seamless finish. It is resistant to cracks, bubbles, and stains, making it ideal for high-traffic areas. Proper preparation of the surface and following the manufacturer’s instructions are essential for achieving a successful epoxy flooring installation. Regular cleaning and maintenance will help prolong the lifespan of epoxy flooring and keep it looking its best.

Epoxy flooring is a popular choice for both residential and commercial spaces in the UK due to its durability, aesthetics, and low maintenance requirements. It is a type of flooring system that consists of a combination of resin and hardener, which chemically react to create a strong and durable surface. Epoxy flooring provides a sleek and shiny finish while also acting as a moisture barrier, making it ideal for areas with regular wear or potential moisture build-up. Proper surface preparation, correct mixing and application techniques, and professional installation by experienced flooring technicians are essential to avoid common issues such as cracks, bubbles, and stains.

True story: A business owner in the UK recently decided to install epoxy flooring in their commercial space. They wanted a durable and visually appealing flooring option that could withstand heavy foot traffic. After consulting with a professional resin flooring specialist and following the recommended installation process, they were able to achieve a flawless epoxy floor that not only enhanced the aesthetic appeal of their space but also provided long-lasting durability. The business owner was extremely satisfied with the outcome and continued to receive compliments on their sleek and shiny epoxy flooring.

Epoxy flooring is popular for several reasons. Firstly, it is highly durable and resistant to wear, impact, and chemicals, making it perfect for high-traffic areas. Additionally, epoxy floors are easy to clean and maintain, requiring only regular cleaning to keep them looking their best. Furthermore, epoxy floors offer aesthetic appeal as they come in a wide range of colours and finishes, allowing for customisation and creating visually appealing spaces. Moreover, epoxy floors have a long lifespan, making them a cost-effective flooring option in the long run. Lastly, epoxy can be applied to various surfaces such as concrete, metal, and wood, making it suitable for both residential and commercial spaces.

When it comes to epoxy flooring, there are a few common problems that can occur. From cracks and bubbles to stains, these issues can be quite troublesome. In this section, we will discuss each of these problems, including their causes and potential solutions. If you want to keep your epoxy floor in perfect condition, stay with us and we will guide you on how to eliminate these issues.

Cracks in epoxy flooring can be a common problem if not properly prevented. To avoid cracks in epoxy flooring, follow these tips:

By following these prevention tips, you can ensure that your epoxy flooring remains crack-free and maintains its durability over time. Remember that seeking the help of qualified flooring technicians can help ensure the best results.

Bubbles in epoxy flooring can be unsightly and compromise the integrity of the floor. Here are some prevention tips to avoid this issue:

Properly prepare the surface by thoroughly cleaning and degreasing it.

Use the correct roller or applicator to ensure even application.

Follow the manufacturer’s guidelines for mixing and applying the epoxy.

Avoid moisture and air getting trapped under the epoxy by eliminating any sources of moisture and ensuring proper ventilation during application.

By following these tips, you can minimize the chances of bubbles forming in your epoxy flooring and achieve a smooth and professional finish.

Bubbles forming in epoxy flooring have been a common issue for many years. Contractors and DIY-ers alike have faced challenges in achieving a bubble-free surface. With advancements in epoxy technology and improved application techniques, the occurrence of bubbles has significantly reduced in modern epoxy flooring systems. Professional resin flooring specialists now have the expertise and equipment needed to prevent and address this issue, ensuring a flawless and long-lasting finish.

Stains on epoxy flooring can be unsightly and difficult to remove if not properly addressed. Here are some prevention tips to keep your epoxy floor free from stains:

Regular Cleaning and Maintenance: Clean spills promptly using a mild detergent and a soft cloth or mop.

Using Appropriate Cleaning Products: Avoid harsh chemicals that can damage or discolour the epoxy floor. Use pH-neutral cleaners recommended for epoxy surfaces.

Protective Measures to Minimise Spills: Place mats or rugs in high-traffic areas or areas prone to spills to prevent direct contact with the epoxy floor.

Fact: Did you know that epoxy flooring is known for its durability and resistance to stains, making it a popular choice for commercial and industrial spaces?

Prevention Tips for Cracks in Epoxy Flooring

Maintaining the durability and aesthetic appeal of epoxy flooring requires preventing cracks. This section explores practical tips to ensure your epoxy flooring remains crack-free. From proper surface preparation to selecting the suitable epoxy coating and applying it in ideal environmental conditions, we provide valuable insights to help you prevent cracks in your epoxy flooring. These expert tips will help you bid farewell to the headaches caused by cracked flooring.

Proper surface preparation is essential for the successful installation of epoxy flooring. Follow these steps for effective surface preparation:

Proper surface preparation has been a critical aspect of flooring installations for centuries. Ancient Romans used crushed stone and lime mortar to create durable and aesthetically pleasing surfaces. By meticulously preparing the surfaces, they were able to achieve long-lasting and beautiful floors. This practice has continued to evolve over time, with modern technologies and techniques ensuring that floors not only look good but also withstand the test of time. Today, qualified flooring technicians employ advanced methods and utilize industrial-grade equipment to ensure proper surface preparation, resulting in flawless epoxy flooring installations.

Choosing the right epoxy coating is crucial to ensure a successful and long-lasting installation of epoxy flooring. Here are the steps you should follow when selecting the appropriate epoxy coating:

Applying epoxy in ideal environmental conditions is crucial to ensure a successful and durable flooring installation.

Historically, applying epoxy in ideal environmental conditions has been essential for achieving high-quality and long-lasting epoxy flooring. In ancient Egypt, builders had to carefully choose the time of year and temperature to apply resin-based coatings to their structures. They noticed that applying epoxy during hot and humid days led to poor adhesion, while cool and dry conditions produced a flawless finish. This ancient wisdom continues to guide modern-day epoxy flooring specialists in ensuring optimal conditions for successful installations.

Prevention Tips for Bubbles in Epoxy Flooring

Achieving a flawless finish in epoxy flooring requires preventing bubbles. This section will provide the best tips to ensure bubble-free epoxy surfaces. The tips include eliminating trapped moisture and air, selecting the appropriate roller or applicator, and mastering proper mixing and application techniques. With this knowledge and skillset, you can prevent bubbles from appearing in your epoxy flooring and enjoy a smooth, seamless floor.

To eliminate moisture and air trapped under epoxy flooring, follow these steps:

Prepare the surface: Ensure the concrete floor is clean, dry, and free of any contaminants.

Apply a moisture barrier: Use a manufacturer-recommended primer or moisture-blocking system to prevent moisture vapor transmission.

Eliminate air and moisture: Use a degreasing treatment to remove any oils or residues from the surface.

Apply epoxy in correct proportions: Mix the epoxy resin and hardener in the perfect ratio recommended by the manufacturer.

Choose the right roller or applicator: Use the correct tools to apply the epoxy evenly and avoid trapping air or moisture.

Properly cure the epoxy: Allow the epoxy to cure in the recommended air temperature and humidity conditions to ensure it hardens correctly.

By following these steps, you can prevent moisture and air from becoming trapped under the epoxy, resulting in a smooth and long-lasting finish. Remember to consult a professional resin flooring specialist for expert advice and installation.

Choosing the right roller or applicator is essential for a successful epoxy flooring installation. Here are some steps to consider:

Choose an applicator based on the size and type of the area you’re coating. For large areas, use a roller, and for smaller, detailed sections, use a brush.

Select the appropriate nap length for the roller, depending on the thickness of the epoxy and the desired texture.

Ensure that the roller or brush is clean and free of any debris or loose fibers that could contaminate the epoxy.

Follow the manufacturer’s instructions for proper mixing and application techniques.

Pro-tip: For larger areas, consider using a squeegee as it allows for quick and even application of the epoxy, resulting in a smoother finish.

Proper mixing and application techniques are essential for a successful epoxy flooring installation. To achieve a smooth and durable finish, follow these steps:

Pro-tip: If you are unsure about the mixing and application process, it is recommended to consult a professional resin flooring specialist for expert guidance and a flawless finish.

When it comes to maintaining the pristine condition of your epoxy flooring and preventing stains, it is important to focus on prevention. This section provides valuable tips and tricks to help you eliminate stubborn stains on your epoxy floors. From regular cleaning and maintenance to using the appropriate cleaning products and implementing protective measures, we have all the information you need. Let’s delve into the details and explore how you can keep your epoxy flooring looking flawless and free from any issues.

Regular cleaning and maintenance are essential for preserving the quality and appearance of epoxy flooring. To ensure the longevity of your epoxy floor, follow these important steps:

Using appropriate cleaning products is essential for maintaining the longevity and appearance of epoxy flooring. To ensure proper cleaning, follow these steps:

By following these protective measures, you can minimize the risk of spills and maintain the integrity of your epoxy flooring.

Epoxy flooring problems can include peeling and blistering, discoloration and fading, cracking and chipping, uneven finish, and a slippery surface.

Peeling and blistering can be caused by improper surface preparation, not using a primer, poor quality epoxy, applying epoxy in unsuitable temperatures, humidity problems, incorrect preparation of the epoxy mixture, and not allowing the epoxy to cure properly.

To prevent peeling and blistering in epoxy floors, it is important to thoroughly clean the surface, use a manufacturer-recommended primer, ensure proper surface preparation, use high-quality epoxy products, apply epoxy in suitable temperatures, address humidity issues, prepare the epoxy mixture correctly, and allow the epoxy to cure properly.

An uneven finish in epoxy flooring can be caused by improper surface preparation, improper installation, inconsistent application, or the use of low-quality epoxy products.

To avoid an uneven finish in epoxy flooring, it is important to properly prepare the surface, use professional flooring services, ensure consistent application, and choose high-quality epoxy products.

Epoxy flooring enhances safety by addressing moisture and humidity issues, implementing proper maintenance and care, and adding non-slip agents to reduce the risk of accidents.

We Aim To Reply To All Enquiries With-in 24-Hours